Enhancing Supply Chain Visibility in Chemical Manufacturing through Integrated Planning Systems

In chemical manufacturing, where regulatory compliance, hazardous material handling, and dynamic market demands intersect, supply chain visibility is not just a competitive advantage—it’s a critical necessity. For Supply Chain Managers, the ability to see and respond to disruptions across sourcing, production, and distribution networks in real time directly impacts both safety and profitability.

However, traditional enterprise systems often fall short in delivering actionable insights across the entire supply chain. That's where Advanced Planning and Scheduling (APS) tools like PlanetTogether, when integrated with robust ERP and MES platforms such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, can revolutionize the visibility landscape.

This blog explores how integrating APS with ERP/MES platforms enhances supply chain visibility for chemical manufacturers and empowers Supply Chain Managers to achieve greater responsiveness, efficiency, and compliance.

The Visibility Challenge in Chemical Manufacturing

Chemical supply chains are among the most complex in the manufacturing world. The challenges include:

Batch production variability

Hazardous materials handling and regulatory tracking

Volatile commodity pricing

Strict environmental and safety compliance requirements

Demand unpredictability from downstream industries

Despite significant investment in ERP systems, many Supply Chain Managers still grapple with fragmented data, manual coordination, and limited real-time visibility. The lack of synchronization between production, procurement, and logistics results in suboptimal decisions and reactive planning.

The Case for Advanced Planning and Scheduling (APS)

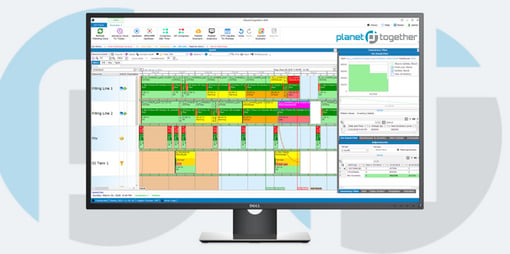

APS platforms like PlanetTogether provide the functionality to simulate, model, and optimize supply chain processes in real time. By centralizing data and providing a dynamic planning environment, PlanetTogether offers:

Real-time visualization of production schedules

Scenario planning to assess impacts of disruptions

Optimized scheduling to maximize throughput

Inventory and capacity balancing

KPI dashboards for proactive decision-making

Yet the real magic happens when PlanetTogether is tightly integrated with ERP and MES systems—turning what used to be isolated data streams into a unified, decision-ready landscape.

Integration: PlanetTogether + ERP/MES Systems

Integration between PlanetTogether and enterprise platforms like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva allows supply chain teams to unlock transformative visibility benefits. Here's how:

End-to-End Transparency

With real-time data flowing between systems, Supply Chain Managers can monitor every link—from raw material procurement through production to customer delivery—on a single, dynamic platform.

Example:

A delay in raw material shipment detected in SAP triggers an automatic rescheduling in PlanetTogether. The scheduler sees the impact across production lines, adjusts priorities, and informs logistics—all without manual data entry.

Better Demand-Supply Matching

Kinaxis and Oracle users benefit from advanced demand forecasting, but without APS integration, those forecasts don’t easily translate into optimized production schedules. PlanetTogether bridges this gap, aligning forecasts with resource availability and production capacity.

Benefit:

Reduced stockouts, minimized excess inventory, and synchronized procurement.

Improved Regulatory Compliance

Aveva MES tracks operational compliance, while PlanetTogether overlays planning data, enabling traceable batch production aligned with regulatory mandates. Integrated systems can also automate documentation, ensuring audit readiness.

Faster Response to Disruptions

In chemical manufacturing, minor disruptions can escalate quickly. Integration enables real-time updates: a production halt in Microsoft Dynamics triggers PlanetTogether to reroute or reschedule jobs, minimizing downtime and waste.

Key Visibility Features Unlocked by Integration

Dynamic Gantt Charts & Heat Maps

Visualize bottlenecks and capacity constraints before they become issues.

Automated Alerts & Exception Handling

Receive instant notifications when plans deviate from KPIs or compliance parameters.

Real-Time KPI Dashboards

Monitor key supply chain metrics like OTIF (On-Time-In-Full), inventory turnover, and capacity utilization.

What-If Scenario Planning

Simulate outcomes of supplier delays, increased demand, or resource outages without impacting the live schedule.

Role-Based Access

Provide visibility to stakeholders across procurement, planning, and logistics—each with customized views.

Visibility as a Competitive Advantage

In the chemical manufacturing environment, supply chain visibility is more than a technical enhancement—it’s a strategic imperative. Disconnected systems and reactive planning no longer suffice.

By integrating PlanetTogether APS with ERP and MES platforms such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, Supply Chain Managers can elevate visibility, reduce risk, and drive more responsive, efficient operations. The result is not just cost savings, but a smarter, more agile supply chain—ready for anything the market throws its way.

Looking to transform your supply chain visibility? Reach out for a demo today to learn more about how PlanetTogether can integrate seamlessly with your ERP and MES ecosystem to give you the clarity and control your chemical manufacturing operations need.