As with most manufacturing operations, operations managers in the food and beverage industry must balance quantity, quality, and costs of production while considering the needs and preferences of customers. This is why it is essential to develop a plan for your production process.

As with most manufacturing operations, operations managers in the food and beverage industry must balance quantity, quality, and costs of production while considering the needs and preferences of customers. This is why it is essential to develop a plan for your production process.

A common challenge encountered by managers that are solely using and ERP or MRP software is that these solutions assume infinite capacity. Most of the time, these solutions use lead times, queue times, and processing times to set their target completion dates without taking into consideration whether they have enough resource capacity to complete the work on time.

Using an Advanced Planning and Scheduling (APS) system with finite capacity planning will help you increase your operational efficiency and ensure that your production schedule is realistic so that you can fulfill your customer requirements and fulfillment times. With finite capacity scheduling, operations are only scheduled when resources and materials are available.

In addition, an APS system will schedule production using other constraints such as resource capability, batch size, shelf life, item compatibility, and more.

With high market volatility and unpredictable buying habits from consumers, there is a need for a planning and scheduling software that allows you to develop an accurate demand forecast so that you can ensure that you will have the ingredients and resource capacity you need to carry out the plan.

Before implementing finite scheduling into your manufacturing operation, it is essential to understand its benefits and how it pertains to the food and beverage industry.

Benefits of Finite Scheduling in the Food and Beverage Industry

The benefits pertaining to finite scheduling in the food and beverage industry include:

- Reduced Scheduling Efforts - Many manufacturers will spend an extensive amount of time attempting to locate the most advantageous schedule for their food production process. Finite scheduling enables manufacturers to be able to utilize “what-if” scenarios that allow them to locate the most advantageous schedule without making any actual changes to production. This ultimately leads to reduced scheduling efforts and less time required to develop an adequate schedule for your production if any quick changes are needed.

- Real-Time Information - The ultimate goal of modern-day manufacturers is to fulfill customer obligations as quickly as possible. This is facilitated by having access to real-time information as opposed to theoretical data as it is much more reliable and provides additional insight into the current operation. Finite scheduling softwares that use real-time information will allow planners and schedulers to create the most realistic schedule and ensure that orders are given enough time to be completed.

- Waste Reduction - Advanced Planning and Scheduling softwares are able to clean up the production process and make much more efficient use of available resources which allows manufacturers to reduce waste within their operations. This allows for the production process to cost less, which will increase the amount of money that is returned. In addition, softwares that take material shelf life and batching into consideration will allow manufacturers to use up the material they have in inventory before it spoils.

- Inventory Reduction - Inventory-related costs can be some of the highest within manufacturing. This is why manufacturers should seek to move the materials and products they have in inventory as quickly as possible. Finite scheduling with advanced planning and scheduling software will allow you to reduce your inventory levels by only purchasing materials for when they are needed. The improved production flow will eliminate inefficiencies and bottlenecks within the operations and make your operations leaner.

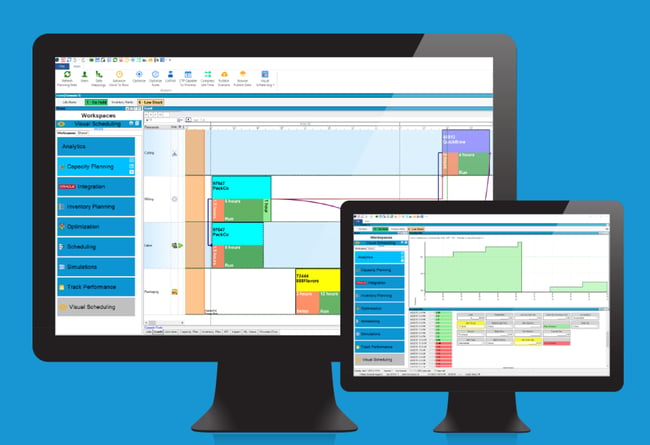

PlanetTogether’s Advanced Planning and Scheduling system knows which resources can perform which type of work, when these resources are available, when the material is available, and the run rates of the resources. The system can then take all of this information into consideration and automatically generate a production schedule that is actually feasible based on the amount of capacity available on your resources.

PlanetTogether is easier. Its color-coordinated functionality makes the schedule simple to scan, and data is easily modified to fit our specific needs. I can look at my screen and know exactly when we’re running decaffeinated coffee, know when jobs will be late, on time, and the case quantities. I see everything on one screen.

JAIME OZUNA, PRODUCTION SCHEDULER, ATLANTIC COFFEE

Advanced Planning and Scheduling (APS) Software is a must for manufacturing operations that are seeking to increase profitability, reduce waste, and fulfill any customer obligations in terms of fulfillment times and quality.

Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling Softwares have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free trial or demo!

Related Multi Plant Video

APS Resources