Mastering Just-in-Time Inventory Management Strategies in Pharmaceutical Manufacturing

Learn how Production Planners in pharmaceutical manufacturing can optimize efficiency with JIT inventory management strategies & software integration.

Learn how integrated solutions optimize chemical manufacturing by identifying and mitigating bottlenecks, enhancing efficiency.

Every facility aims to optimize production processes, minimize downtime, and maximize output. However, bottlenecks can hinder these objectives, causing delays, increased costs, and missed opportunities. Addressing these bottlenecks effectively requires a comprehensive understanding of the manufacturing ecosystem and leveraging advanced technologies for streamlined operations.

In this blog, we look into the intricacies of bottleneck identification and mitigation strategies within chemical manufacturing facilities. We'll explore how integrating advanced planning and scheduling solutions like PlanetTogether with leading ERP (Enterprise Resource Planning), SCM (Supply Chain Management), and MES (Manufacturing Execution Systems) platforms such as SAP, Oracle, Microsoft, Kinaxis, and Aveva can revolutionize operations, leading to enhanced efficiency and profitability.

Bottlenecks refer to any point in the production process where the flow of materials or information is impeded, leading to decreased throughput and overall inefficiency. These bottlenecks can occur due to various reasons, including equipment limitations, resource constraints, inefficient workflows, or poor planning.

Identifying bottlenecks necessitates a holistic approach, involving data analysis, process mapping, and real-time monitoring. Modern manufacturing IT solutions offer powerful tools for capturing and analyzing vast amounts of data generated throughout the production cycle. By leveraging advanced analytics and machine learning algorithms, manufacturers can pinpoint bottlenecks with precision, allowing for targeted interventions.

![]()

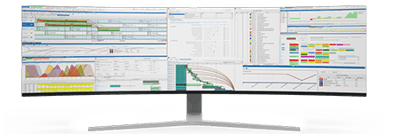

Integration between planning and scheduling solutions like PlanetTogether and ERP, SCM, and MES systems is instrumental in achieving seamless coordination across the manufacturing landscape. These integrations enable real-time data exchange, providing stakeholders with enhanced visibility into critical operations and enabling proactive decision-making.

For instance, integrating PlanetTogether with SAP's ERP system allows for synchronized production planning and inventory management. By leveraging SAP's comprehensive data infrastructure alongside PlanetTogether's advanced scheduling algorithms, manufacturers can optimize resource allocation, minimize lead times, and mitigate bottlenecks effectively.

Similarly, integration with Oracle's SCM platform facilitates end-to-end supply chain visibility, enabling manufacturers to anticipate demand fluctuations and adjust production schedules accordingly. This integration empowers organizations to proactively address potential bottlenecks by reallocating resources or adjusting production priorities in real-time.

Microsoft's Dynamics 365 suite offers another powerful ecosystem for integrating planning and scheduling solutions. By connecting PlanetTogether with Dynamics 365 Supply Chain Management, manufacturers gain access to advanced analytics capabilities and predictive insights, enabling them to identify and mitigate bottlenecks before they escalate.

Furthermore, integration with Kinaxis RapidResponse provides manufacturers with a unified platform for supply chain planning and execution. By combining PlanetTogether's robust scheduling capabilities with Kinaxis' scenario simulation and what-if analysis tools, organizations can develop agile response strategies to address bottlenecks and optimize production efficiency.

Aveva's MES solutions complement PlanetTogether's scheduling capabilities by providing real-time visibility into shop floor operations. Integration between PlanetTogether and Aveva MES enables seamless data exchange between production planning and execution, facilitating rapid response to bottlenecks and ensuring alignment between production goals and operational realities.

Once bottlenecks are identified through integrated IT solutions, manufacturers can implement targeted mitigation strategies to alleviate constraints and enhance overall efficiency. Some effective mitigation strategies include:

Resource Optimization: By reallocating resources based on real-time demand and capacity data, manufacturers can alleviate bottlenecks and ensure optimal utilization of equipment and manpower.

Process Optimization: Continuous process improvement initiatives, supported by data-driven insights from integrated IT systems, enable manufacturers to streamline workflows, eliminate redundant steps, and minimize cycle times.

Capacity Expansion: In some cases, bottleneck mitigation may require investments in additional equipment or infrastructure to increase production capacity and alleviate constraints on throughput.

Supply Chain Collaboration: Collaboration with suppliers and partners is essential for addressing upstream bottlenecks related to raw material availability, transportation delays, or quality issues. Integrated SCM solutions facilitate seamless collaboration and supply chain orchestration.

Predictive Maintenance: Proactive maintenance strategies, enabled by integration between scheduling and maintenance management systems, help prevent equipment breakdowns and minimize downtime due to unplanned maintenance activities.

Effective bottleneck identification and mitigation are critical for optimizing efficiency and competitiveness in chemical manufacturing. By leveraging integrated IT solutions such as PlanetTogether with leading ERP, SCM, and MES platforms, manufacturers can gain unprecedented visibility and control over their operations, enabling them to identify bottlenecks proactively and implement targeted mitigation strategies.

The synergy between advanced planning and scheduling capabilities and comprehensive data infrastructure provided by ERP, SCM, and MES systems empowers manufacturers to achieve operational excellence and drive sustainable growth.

By embracing integration and leveraging data-driven insights, chemical manufacturers can navigate the complexities of modern production environments with confidence, unlocking new levels of efficiency and agility.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Learn how Production Planners in pharmaceutical manufacturing can optimize efficiency with JIT inventory management strategies & software integration.

Learn how integrating advanced planning tools with ERP systems optimizes efficiency and innovation in chemical manufacturing.

Unlock efficiency in chemical manufacturing with advanced capacity planning strategies and integration solutions. Optimize production with ease.

Be the first to know about new B2B SaaS Marketing insights to build or refine your marketing function with the tools and knowledge of today’s industry.