Advanced Supply Chain Risk Management Solutions

Supply Chain Managers face an array of challenges, from regulatory compliance to demand volatility and supplier disruptions in pharmaceutical manufacturing. Managing these complexities efficiently while ensuring product quality and patient safety is paramount. The integration of advanced Supply Chain Risk Management (SCRM) solutions becomes indispensable in navigating these challenges effectively.

In this blog, we'll look into the importance of SCRM in pharmaceutical manufacturing and explore how integration between PlanetTogether and leading ERP, SCM, and MES systems can bolster resilience and agility in the supply chain.

Supply Chain Risk Management in Pharmaceuticals

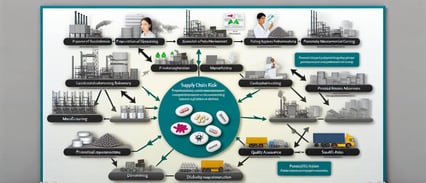

Supply Chain Risk Management (SCRM) encompasses the identification, assessment, and mitigation of risks across the supply chain. In pharmaceutical manufacturing, where product quality and compliance are non-negotiable, effective SCRM is critical. Risks can manifest in various forms, including supply shortages, regulatory changes, natural disasters, and geopolitical uncertainties.

The Consequences of Ineffective SCRM

Failure to address supply chain risks adequately can have dire consequences. Product shortages, regulatory non-compliance, and compromised product quality not only impact revenue but also pose significant risks to patient health and safety. Moreover, the reputational damage incurred from supply chain disruptions can be long-lasting.

The Role of Advanced SCRM Solutions

Advanced SCRM solutions leverage data analytics, predictive modeling, and real-time monitoring to proactively identify and mitigate risks. These solutions enable Supply Chain Managers to anticipate disruptions, optimize inventory levels, and develop contingency plans to mitigate potential impacts. By integrating SCRM into their operations, pharmaceutical manufacturers can enhance agility, responsiveness, and resilience in the face of uncertainties.

Integration between PlanetTogether and Leading ERP, SCM, and MES Systems

PlanetTogether offers advanced production planning and scheduling capabilities, enabling pharmaceutical manufacturers to optimize production processes and resource utilization. However, to achieve end-to-end visibility and agility, integration with leading ERP, SCM, and MES systems is imperative.

Integration with SAP: SAP's ERP system provides robust enterprise-wide functionalities, including procurement, inventory management, and compliance management. By integrating with PlanetTogether, SAP users can synchronize production schedules with real-time demand data, streamline order fulfillment processes, and improve supply chain visibility.

Integration with Oracle: Oracle's SCM solutions offer comprehensive supply chain planning and execution capabilities. Integration with PlanetTogether enables pharmaceutical manufacturers to align production schedules with demand forecasts, optimize inventory levels, and collaborate effectively with suppliers and distributors.

Integration with Microsoft Dynamics: Microsoft Dynamics provides flexible and scalable ERP solutions tailored to the needs of pharmaceutical manufacturers. By integrating with PlanetTogether, Microsoft Dynamics users can automate production scheduling, enhance resource utilization, and minimize lead times, thereby improving operational efficiency and customer satisfaction.

Integration with Kinaxis: Kinaxis' RapidResponse platform offers end-to-end supply chain visibility and scenario planning capabilities. Integration with PlanetTogether empowers Supply Chain Managers to assess the impact of potential disruptions, simulate various scenarios, and implement proactive risk mitigation strategies, ensuring continuity of operations and customer satisfaction.

Integration with Aveva: Aveva's MES solutions enable real-time monitoring and control of manufacturing processes. By integrating with PlanetTogether, Aveva users can synchronize production schedules with shop floor activities, optimize resource allocation, and ensure compliance with regulatory requirements, thereby enhancing operational efficiency and product quality.

In the high-stakes environment of pharmaceutical manufacturing, Supply Chain Managers must adopt advanced SCRM solutions to mitigate risks effectively and ensure business continuity. Integration between PlanetTogether and leading ERP, SCM, and MES systems empowers pharmaceutical manufacturers to enhance agility, responsiveness, and resilience in the face of uncertainties.

By leveraging these integrated solutions, organizations can navigate the complexities of the supply chain landscape with confidence, safeguarding product quality, patient safety, and long-term success.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.