Leveraging Data-driven Strategies for Sustainable Profitability

In pharmaceutical manufacturing, achieving sustainable profitability while maintaining compliance and meeting demand can be a daunting task. Production schedulers play a crucial role in this endeavor, as they are responsible for orchestrating the intricate dance of production processes, resources, and timelines.

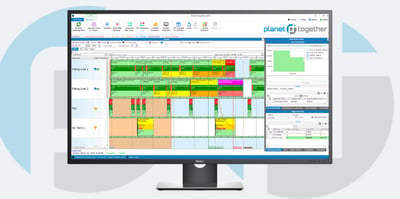

In recent years, the advent of advanced planning and scheduling (APS) software solutions, such as PlanetTogether, coupled with integration capabilities with enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES) like SAP, Oracle, Microsoft, Kinaxis, and Aveva, has revolutionized the way pharmaceutical companies approach production scheduling.

In this blog, we'll look into the realm of data-driven strategies for production scheduling in pharmaceutical manufacturing and explore how the integration of APS with ERP, SCM, and MES systems can drive sustainable profitability.

Understanding the Challenges

It's essential to understand the challenges that production schedulers face in pharmaceutical manufacturing:

Regulatory Compliance: Pharmaceutical manufacturing is governed by stringent regulations to ensure product safety and efficacy. Production schedules must adhere to regulatory requirements, leading to complexity and limited flexibility.

Demand Variability: Fluctuating demand patterns, driven by factors such as seasonality, market trends, and unforeseen events, pose challenges for production planning and scheduling.

Resource Optimization: Efficient utilization of resources, including equipment, materials, and personnel, is critical for maintaining profitability while ensuring product quality and meeting delivery timelines.

Complex Supply Chain: The pharmaceutical supply chain is multifaceted, involving various stakeholders and processes. Coordinating activities across the supply chain while minimizing disruptions is a considerable challenge.

Data-driven Strategies for Sustainable Profitability

Data-driven strategies empower production schedulers with the insights needed to make informed decisions, optimize processes, and drive sustainable profitability. By harnessing the power of data analytics, machine learning, and advanced planning algorithms, pharmaceutical companies can address the challenges mentioned earlier effectively.

Demand Forecasting and Predictive Analytics

Accurate demand forecasting is foundational to effective production scheduling. By analyzing historical sales data, market trends, and other relevant factors, production schedulers can generate more accurate demand forecasts. Predictive analytics techniques, such as time series analysis and machine learning algorithms, can further enhance forecasting accuracy by identifying patterns and trends.

Integrating APS software with ERP and SCM systems enables real-time data exchange, ensuring that production schedules are continuously updated based on the latest demand forecasts. This agility allows pharmaceutical companies to respond promptly to changes in demand and optimize production plans accordingly.

Dynamic Scheduling and Optimization

Traditional static scheduling approaches are inadequate in today's dynamic manufacturing environment. Dynamic scheduling techniques, facilitated by APS software, enable production schedulers to create flexible schedules that adapt to changing conditions in real-time. By considering factors such as equipment availability, material availability, and resource constraints, dynamic scheduling algorithms optimize production plans to maximize efficiency and minimize costs.

Integration between APS and MES systems provides visibility into shop floor operations, allowing production schedulers to monitor production progress in real-time. This visibility enables proactive decision-making and facilitates rapid response to issues or delays, ensuring that production schedules stay on track.

Inventory Management and Supply Chain Optimization

Effective inventory management is essential for minimizing carrying costs while ensuring product availability. By integrating APS with ERP systems, production schedulers can gain visibility into inventory levels, track stock movements, and optimize replenishment processes. Just-in-time inventory practices can help reduce excess inventory and streamline supply chain operations, leading to cost savings and improved cash flow.

Supply chain optimization involves synchronizing activities across the supply chain to minimize lead times, reduce costs, and enhance overall efficiency. APS software facilitates collaborative planning and coordination among suppliers, manufacturers, and distributors, enabling seamless integration of supply chain processes.

Integration with ERP, SCM, and MES Systems

The integration of APS with ERP, SCM, and MES systems is crucial for unlocking the full potential of data-driven strategies in pharmaceutical manufacturing. Seamless data exchange between these systems ensures a unified view of operations, enabling end-to-end visibility and control over the entire production process.

PlanetTogether Integration

PlanetTogether offers robust integration capabilities with leading ERP, SCM, and MES systems, including SAP, Oracle, Microsoft, Kinaxis, and Aveva. This integration enables seamless data synchronization and interoperability between production scheduling and other business functions, facilitating streamlined operations and informed decision-making.

By leveraging the integration between PlanetTogether and ERP, SCM, and MES systems, production schedulers can:

- Access real-time data from across the organization, enabling accurate demand forecasting and dynamic scheduling.

- Streamline order management, inventory control, and procurement processes to optimize resource utilization and minimize costs.

- Improve collaboration and communication among cross-functional teams, enhancing agility and responsiveness to changing market conditions.

- Enhance visibility into production processes, enabling proactive identification and resolution of issues to minimize disruptions.

Data-driven strategies, coupled with the integration of APS with ERP, SCM, and MES systems, offer pharmaceutical companies a powerful toolkit for achieving sustainable profitability. By harnessing the power of data analytics, predictive algorithms, and real-time visibility, production schedulers can optimize production schedules, streamline supply chain operations, and drive operational excellence.

As the pharmaceutical industry continues to evolve, embracing innovation and leveraging technology will be critical for staying competitive and meeting the demands of an increasingly complex market landscape. By adopting data-driven approaches and embracing integration between planning and execution systems, pharmaceutical manufacturers can position themselves for success in the quest for sustainable profitability.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in the pharmaceutical industry.