Digital Asset Management Systems for Resource Allocation

Production planners play a pivotal role in ensuring that resources are allocated optimally to meet production targets while minimizing waste and costs. In today's digital age, the integration of advanced technologies like digital asset management systems (DAMS) has revolutionized the way production planning is executed. By leveraging DAMS alongside enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES), production planners can streamline operations and drive productivity to new heights.

In this blog post, we will look into the utilization of DAMS in packaging manufacturing facilities, exploring how these systems enhance resource allocation and facilitate seamless integration with leading ERP, SCM, and MES platforms such as PlanetTogether and SAP, Oracle, Microsoft, Kinaxis, Aveva, and others.

Digital Asset Management Systems

Digital Asset Management Systems serve as centralized repositories for managing, organizing, and distributing digital assets such as product designs, manufacturing specifications, raw material inventories, and production schedules. These systems offer a holistic view of the manufacturing landscape, empowering production planners with real-time insights into available resources, production capacities, and demand forecasts.

Key Features and Benefits of DAMS

Resource Visibility: DAMS provide production planners with comprehensive visibility into available resources, including raw materials, equipment, and labor. This visibility enables planners to make informed decisions regarding resource allocation, ensuring that production runs smoothly without bottlenecks or shortages.

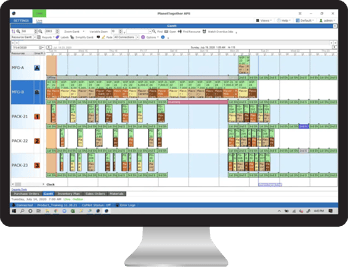

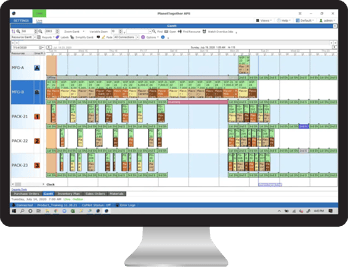

Optimized Scheduling: By integrating DAMS with production planning software like PlanetTogether, planners can create optimized production schedules that maximize resource utilization and minimize downtime. These schedules take into account factors such as equipment availability, production constraints, and customer demand, resulting in efficient production workflows.

Inventory Management: Effective inventory management is critical in packaging manufacturing, where raw material availability directly impacts production output. DAMS facilitate inventory tracking and replenishment, alerting planners when stock levels are low and enabling proactive procurement to prevent supply chain disruptions.

Quality Control: DAMS can store quality control protocols, inspection checklists, and product specifications, ensuring that manufacturing processes adhere to regulatory standards and customer requirements. By maintaining a centralized repository of quality-related assets, packaging manufacturers can uphold product integrity and mitigate the risk of defects or recalls.

Integration with ERP, SCM, and MES Systems

To fully harness the power of DAMS, integration with other enterprise systems such as ERP, SCM, and MES is essential. These integrations enable seamless data exchange between systems, ensuring that production planners have access to accurate and up-to-date information for decision-making.

PlanetTogether, a leading provider of production planning and scheduling software, offers robust integration capabilities with a wide range of ERP systems, including SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva. By integrating PlanetTogether with these ERP systems, packaging manufacturers can achieve the following benefits:

Streamlined Data Exchange: Integration between PlanetTogether and ERP systems facilitates seamless data exchange, ensuring that production planners have access to accurate data on inventory levels, customer orders, and production schedules.

Enhanced Visibility: By consolidating data from multiple sources, integration with ERP systems provides production planners with a comprehensive view of the entire production process, enabling better decision-making and resource allocation.

Improved Accuracy: Integration eliminates manual data entry and reduces the risk of errors, ensuring that production planners are working with accurate and reliable information.

Automated Workflows: Integration between PlanetTogether and ERP systems automates workflows such as order processing, inventory management, and invoicing, streamlining production processes and reducing administrative overhead.

The utilization of digital asset management systems plays a pivotal role in enhancing resource allocation and operational efficiency in packaging manufacturing facilities. By providing production planners with comprehensive visibility, optimized scheduling, inventory management, and quality control capabilities, DAMS enable manufacturers to streamline production workflows, minimize costs, and maximize productivity.

Furthermore, integration with leading ERP, SCM, and MES systems such as PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, and Aveva amplifies the benefits of DAMS by creating a unified ecosystem that synchronizes data and processes across the entire manufacturing enterprise. This integration empowers production planners to make informed decisions, respond quickly to market changes, and drive continuous improvement in packaging manufacturing operations.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.