Leveraging Supply Chain Digital Twins in Pharmaceutical Manufacturing: A Pathway to Precision and Agility

The Rise of Digital Twins in Pharmaceutical Supply Chains

In an industry where precision, compliance, and speed to market are paramount, pharmaceutical manufacturers are increasingly turning to digital twins to transform their supply chain operations. These virtual replicas of physical supply chain systems provide a real-time, dynamic view of processes, assets, and logistics — enabling predictive analysis, proactive decision-making, and holistic optimization.

For Supply Chain Managers navigating an environment shaped by regulatory complexity, market volatility, and evolving patient demands, the integration of digital twin technology with advanced planning and scheduling (APS) systems is not just an innovation — it’s a necessity.

By connecting PlanetTogether APS with leading ERP platforms like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, pharmaceutical manufacturers can create a synchronized, intelligent supply chain framework that enhances visibility, reduces disruptions, and supports continuous improvement.

What is a Supply Chain Digital Twin?

A supply chain digital twin is a real-time, data-driven model that mirrors the entire supply chain ecosystem — from raw material sourcing and manufacturing to distribution and patient delivery. Unlike static dashboards or historical reports, digital twins evolve continuously based on live data feeds, enabling simulation, scenario analysis, and performance monitoring.

For pharmaceutical companies, where manufacturing processes are tightly regulated, lead times are long, and demand patterns are often unpredictable, a digital twin offers the capability to:

Simulate production scenarios and capacity constraints

Predict inventory shortages or bottlenecks

Optimize sourcing strategies

Test regulatory compliance in virtual environments

Enhance collaboration across functions and partners

Why Digital Twins Matter for Pharmaceutical Supply Chains

Pharmaceutical supply chains are among the most complex in the world, with strict quality controls, cold chain logistics, and rigorous compliance standards. The benefits of digital twins in this environment are particularly compelling:

Improved Demand Forecasting

With digital twins, demand signals from various sources — including hospitals, pharmacies, wholesalers, and government agencies — can be integrated into a unified view. Coupled with PlanetTogether’s APS capabilities, this enables predictive forecasting that reduces stockouts and overproduction.

Enhanced Regulatory Compliance

Digital twins allow Supply Chain Managers to simulate the impact of GMP regulations, FDA audits, or serialization requirements across production and logistics processes. When integrated with SAP or Oracle ERP systems, compliance reporting becomes automated and traceable.

Greater Resilience Against Disruption

Using a digital twin, manufacturers can test the effects of supplier shutdowns, transportation delays, or raw material shortages before they occur. This empowers proactive mitigation strategies, such as alternate sourcing or re-sequencing production.

Accelerated New Product Introduction (NPI)

When launching a new drug, speed is critical. Digital twins streamline the planning and execution phases by validating capacity, raw material availability, and logistics networks before scaling up production — minimizing launch delays and cost overruns.

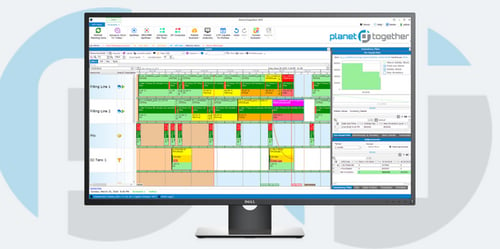

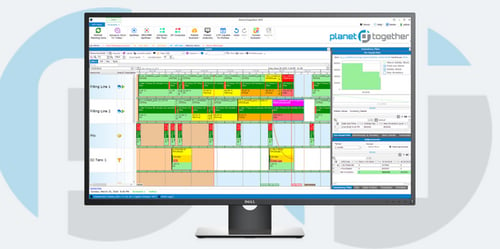

The Role of PlanetTogether in Digital Twin Enablement

PlanetTogether’s Advanced Planning and Scheduling (APS) software acts as a central intelligence layer that synchronizes demand, production, and inventory across the pharmaceutical value chain. When embedded within a digital twin architecture, it enables:

Real-time production scheduling across multiple facilities

Capacity-aware planning that factors in equipment, labor, and material constraints

Simulation of "what-if" scenarios to evaluate decisions before implementation

KPI tracking for continuous performance optimization

Through seamless integration with ERP and MES systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, PlanetTogether becomes the planning engine behind the digital twin — enabling a closed-loop feedback system where insights drive immediate operational adjustments.

Integration in Action: A Realistic Use Case

Consider a pharmaceutical manufacturer producing sterile injectables. Their production involves long lead times, precise temperature controls, and heavy oversight from regulators. Without a digital twin, Supply Chain Managers face limited visibility into bottlenecks, and react only after disruptions occur.

Now, integrate PlanetTogether with SAP S/4HANA in a digital twin framework:

Live production data from MES is fed into the digital twin

Demand changes from the SAP system automatically adjust the APS plan

Simulation models within PlanetTogether test alternate production routes

Alerts are generated if a raw material shipment delay is predicted to impact the batch release schedule

KPIs on cycle time, OEE, and material yield are monitored continuously

This closed-loop model empowers Supply Chain Managers to prevent issues, not just respond to them — aligning supply chain operations with business objectives and regulatory mandates.

Overcoming Implementation Challenges

While the benefits are clear, implementing supply chain digital twins in pharmaceutical manufacturing involves overcoming several challenges:

Data Silos: Disparate systems (ERP, MES, LIMS) need to be integrated through middleware or APIs. PlanetTogether's native connectors with SAP, Oracle, and Microsoft reduce integration friction.

Model Accuracy: Digital twins are only as effective as the quality of their data. Establishing robust master data governance is essential.

Change Management: Introducing digital twins requires cross-functional alignment — from IT and Quality to Operations and Procurement. Senior leadership sponsorship and pilot programs can ease adoption.

Regulatory Constraints: All simulations and data handling must comply with 21 CFR Part 11 and GxP guidelines. Integration platforms like Aveva or Kinaxis offer governance frameworks that support validation and compliance requirements.

In pharmaceutical manufacturing, where the stakes are high and the margins for error are slim, Supply Chain Managers must harness every tool available to drive performance. Digital twins, powered by intelligent planning solutions like PlanetTogether and integrated with robust ERP systems, offer a transformative path forward.

As we move into a future defined by data, speed, and complexity, the digital twin will not be a novelty — it will be the new standard in pharmaceutical supply chain management.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.