Material Inventory: Strategic Visibility and Control in Food & Beverage Manufacturing

Why Inventory Control is the Pulse of Food & Beverage Operations

In food and beverage manufacturing, material inventory is more than just raw ingredients and packaging supplies—it’s the heartbeat of operations. From perishability and regulatory requirements to demand volatility and seasonal supply chains, effective inventory management ensures production doesn’t stall, waste is minimized, and compliance is upheld. For Operations Directors, maintaining full visibility and strategic control over inventory is critical for optimizing output, ensuring food safety, and keeping costs in check.

As the industry undergoes digital transformation, Advanced Planning and Scheduling (APS) solutions like PlanetTogether, when integrated with enterprise systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, provide the holistic visibility and dynamic planning capabilities required to elevate inventory practices from reactive to predictive.

The Unique Challenges of Inventory Management in Food & Beverage

Managing inventory in the food and beverage sector brings a distinct set of challenges that differ from other manufacturing industries:

Shelf Life Sensitivity: Raw materials and finished products are perishable, necessitating strict First-Expiry-First-Out (FEFO) or First-In-First-Out (FIFO) policies.

Batch Traceability: Regulatory compliance requires lot tracking from source to shelf, especially in the case of recalls.

Volatile Demand: Consumer preferences shift quickly, influenced by trends, health guidelines, and seasonality.

Storage Constraints: Cold chain requirements and warehouse capacity demand highly efficient space and energy management.

Supply Chain Variability: Sourcing from agriculture or global suppliers exposes manufacturers to disruptions due to climate, logistics, and tariffs.

Given this landscape, traditional inventory systems and spreadsheet-driven methods are no longer sufficient. What’s needed is a responsive, integrated, and intelligent approach to inventory planning.

The Role of APS in Material Inventory Planning

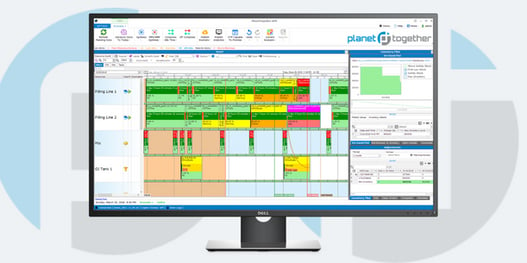

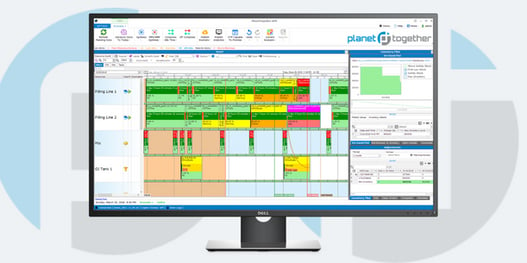

An Advanced Planning and Scheduling (APS) system like PlanetTogether provides a centralized platform to align demand forecasting, material availability, and production schedules in real-time. When connected to ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, the APS becomes a powerhouse for synchronized planning and execution.

Key benefits of integrating APS with ERP systems for inventory management include:

Real-Time Material Visibility

APS integration ensures all inventory data—raw materials, intermediates, packaging, and finished goods—are up-to-date and visible across departments. It allows Operations Directors to answer critical questions instantly:

What materials are available for today's production run?

When will the next shipment of high-turnover ingredients arrive?

Are there any aging batches approaching expiration?

Automated Lot and Batch Control

PlanetTogether, with its batch-aware scheduling, can optimize production runs based on material shelf life. When integrated with SAP or Oracle, for example, it enables automatic alignment of raw material expiry dates with production orders. This ensures minimal waste, better compliance, and smarter utilization of on-hand stock.

Just-in-Time (JIT) Material Flow

By using APS tools connected with systems like Kinaxis or Microsoft Dynamics, food manufacturers can adopt lean principles and maintain optimal inventory levels. Material requirements planning (MRP) can be dynamically adjusted based on real-time production constraints, supplier delays, or changes in customer demand.

Scenario Planning and Risk Mitigation

What happens if your tomato puree shipment is delayed by two days? What’s the impact of a sudden spike in dairy demand on your current stock levels? With PlanetTogether’s simulation and “what-if” capabilities, Operations Directors can model various inventory scenarios and evaluate the most cost-effective responses. Integrated systems ensure these simulations reflect actual constraints from procurement, finance, and production.

Traceability and Regulatory Compliance

Food safety compliance mandates full traceability. When PlanetTogether APS is synchronized with ERP solutions like Aveva or SAP, every step of material usage—from supplier receipt to finished product shipment—is logged and traceable. In the event of a recall or audit, data can be pulled instantly and confidently.

From Forecasting to Floor: How Integration Powers Precision

Let’s explore a real-world workflow showing the power of integrated APS and ERP systems:

Demand Forecasting in ERP

The sales and marketing team inputs seasonal forecasts into Microsoft Dynamics 365.

APS Receives and Analyzes Forecasts

PlanetTogether pulls forecast data and aligns it with current material inventory.

Optimized Material Planning

APS recommends material purchase orders and production schedules based on availability, shelf life, and machine constraints.

Execution and Monitoring

Operators receive schedules through the integrated interface, and materials are issued from inventory in the correct sequence.

Continuous Feedback Loop

If a shipment delay is detected or a production anomaly occurs, PlanetTogether recalculates and synchronizes changes with the ERP—triggering new procurement or adjusting batch runs.

This tight integration avoids the pitfall of overproduction, reduces emergency purchases, and enables reliable, data-driven decisions.

KPIs That Matter: What to Track in Inventory Optimization

Operations Directors should prioritize the following metrics to measure the impact of APS integration on inventory performance:

Inventory Turnover Ratio

Higher turnover suggests efficient use of stock and reduced holding costs.

Waste and Obsolescence Rate

Tracks spoilage or expiry-related losses.

Service Level Fulfillment

Percentage of orders fulfilled without delay due to stockouts.

Production Downtime Due to Inventory Shortage

Reveals how often material unavailability disrupts the schedule.

Inventory Accuracy

Discrepancy between physical counts and system records—crucial for audits and compliance.

With APS like PlanetTogether feeding precise inventory needs and consumption forecasts to the ERP system, these KPIs become actionable rather than historical.

The Competitive Advantage: Why It Matters Now

In 2025, success in food and beverage manufacturing depends on the ability to meet demand with speed, safety, and sustainability. Inventory that’s either too low or too high directly impacts profit margins and brand reputation. Supply chain instability, cost pressures, and ESG goals add more complexity.

By combining PlanetTogether APS with robust ERP ecosystems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, Operations Directors gain a strategic command center. It transforms inventory planning from a cost center to a value driver—empowering manufacturers to:

Respond faster to demand shifts.

Reduce waste and improve sustainability metrics.

Enhance collaboration between procurement, planning, and production.

Meet compliance with confidence.

Avoid costly surprises in both overstock and shortages.

From Reactive to Proactive Inventory Leadership

The time for siloed inventory management is over. In the dynamic, regulation-heavy world of food and beverage manufacturing, Operations Directors must lead with intelligence, agility, and real-time insight. Advanced Planning and Scheduling software like PlanetTogether, when integrated with enterprise platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, offers the visibility and control required to master material inventory.

It’s not just about keeping track of ingredients—it’s about aligning every grain, drop, and box with your factory’s operational goals, sustainability mandates, and customer expectations.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.