Leveraging Artificial Intelligence for Process Optimization

In packaging manufacturing, staying ahead of the competition requires more than just efficient processes—it demands innovation and adaptability. Supply Chain Managers play a crucial role in ensuring the smooth operation of the manufacturing facility, optimizing processes, and driving efficiency gains. In recent years, the integration of artificial intelligence (AI) technologies has emerged as a game-changer, offering unprecedented opportunities for process optimization.

This blog explores how AI can revolutionize packaging manufacturing, with a focus on its integration with leading Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) like PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, Aveva, and others.

The Role of Supply Chain Managers in Packaging Manufacturing

Before looking into the specifics of AI integration, let's first understand the critical role Supply Chain Managers play in packaging manufacturing. These professionals are responsible for overseeing the entire supply chain, from raw material procurement to distribution of finished products. Their primary objectives include minimizing costs, optimizing inventory levels, ensuring timely delivery, and maintaining quality standards. Achieving these goals requires effective coordination of various processes across the supply chain.

Enter Artificial Intelligence

Artificial intelligence offers a paradigm shift in how packaging manufacturing processes can be optimized. By leveraging advanced algorithms and machine learning techniques, AI systems can analyze vast amounts of data, identify patterns, and make data-driven decisions in real-time. This enables Supply Chain Managers to proactively address challenges and capitalize on opportunities for improvement across the entire supply chain.

Integration with ERP, SCM, and MES Systems

The integration of AI with leading ERP, SCM, and MES systems such as PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, Aveva, and others is key to unlocking its full potential in packaging manufacturing. These systems serve as the backbone of the manufacturing operations, providing a centralized platform for data management and process orchestration. By integrating AI capabilities directly into these systems, Supply Chain Managers can seamlessly incorporate AI-driven insights into their decision-making processes.

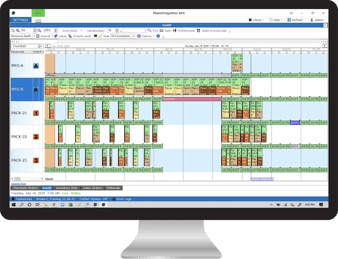

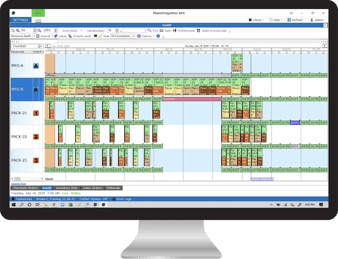

Integration with PlanetTogether: PlanetTogether is a powerful production planning and scheduling software that optimizes manufacturing operations. By integrating AI algorithms with PlanetTogether, Supply Chain Managers can enhance production efficiency by predicting demand fluctuations, optimizing production schedules, and minimizing downtime. AI-powered insights can also help identify potential bottlenecks and recommend proactive measures to mitigate them, ensuring smooth operations.

Integration with SAP, Oracle, and Microsoft: These ERP giants play a crucial role in managing various aspects of packaging manufacturing, including procurement, inventory management, and order fulfillment. By integrating AI with SAP, Oracle, and Microsoft ERP systems, Supply Chain Managers can improve demand forecasting accuracy, streamline inventory optimization, and automate repetitive tasks. AI-driven insights can also enable dynamic pricing strategies based on market trends and customer preferences, maximizing profitability.

Integration with Kinaxis and Aveva: Kinaxis and Aveva offer comprehensive SCM and MES solutions tailored to the needs of manufacturing industries. By integrating AI with Kinaxis and Aveva systems, Supply Chain Managers can optimize supply chain visibility, improve production efficiency, and enhance quality control processes. AI-powered analytics can analyze production data in real-time, detect anomalies, and trigger automated responses to ensure timely resolution of issues.

Benefits of AI for Process Optimization

The utilization of AI for process optimization in packaging manufacturing offers several benefits:

Improved Efficiency: AI-driven insights enable Supply Chain Managers to identify inefficiencies and streamline processes, leading to improved productivity and resource utilization.

Enhanced Quality Control: AI algorithms can analyze production data to detect defects and anomalies in real-time, allowing for proactive quality control measures to be implemented.

Optimized Inventory Management: By accurately predicting demand fluctuations, AI helps minimize excess inventory and stockouts, leading to cost savings and improved customer satisfaction.

Dynamic Decision-Making: AI-powered systems provide Supply Chain Managers with real-time insights and recommendations, enabling them to make data-driven decisions quickly and effectively.

Adaptive Planning: AI algorithms can adapt to changing market conditions and customer preferences, allowing for more agile and responsive planning and execution processes.

The utilization of artificial intelligence for process optimization holds immense potential for revolutionizing packaging manufacturing. By integrating AI with leading ERP, SCM, and MES systems such as PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, Aveva, and others, Supply Chain Managers can unlock new levels of efficiency, agility, and competitiveness. The benefits of AI-driven insights extend across the entire supply chain, from demand forecasting and production planning to inventory management and quality control.

As technology continues to evolve, embracing AI will be essential for packaging manufacturers looking to stay ahead in today's dynamic marketplace. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.