Rapid Response to Changing Demands: How Production Schedulers in Medical Manufacturing Can Stay Ahead with APS Integration

In medical manufacturing, the ability to rapidly respond to changes in demand is not just an operational advantage—it is a matter of public health, compliance, and corporate survival. For production schedulers, these constant shifts present a daily challenge: how to maintain efficiency, ensure regulatory compliance, and meet stringent delivery timelines, all while contending with volatile market dynamics and supply disruptions.

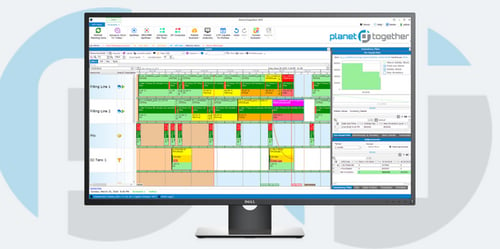

Fortunately, advanced planning and scheduling (APS) tools like PlanetTogether, especially when integrated with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, are revolutionizing how production schedulers manage uncertainty.

This blog explores how integrated APS solutions empower schedulers in medical manufacturing facilities to respond rapidly and strategically to changing demand.

The Unique Challenge of Demand Variability in Medical Manufacturing

Medical manufacturers often deal with erratic and sensitive demand curves. A sudden spike in the need for diagnostic devices, personal protective equipment (PPE), or essential drugs can occur due to unpredictable factors such as:

Disease outbreaks or pandemics

Regulatory approvals for new medical devices or treatments

Geopolitical disruptions or sanctions

Policy changes and government procurement programs

These shifts require production schedules that can pivot almost instantly—without creating bottlenecks, compliance risks, or material shortages. Legacy scheduling systems and manual spreadsheets are no longer sufficient in today’s fast-paced environment.

The Strategic Role of the Production Scheduler

Production schedulers are at the front lines of this complexity. They must:

Balance limited production capacity with urgent order volumes

Prioritize SKUs based on profitability, criticality, or expiration date

Manage cleanroom schedules, equipment validations, and cross-contamination risks

Avoid material waste due to obsolescence or overproduction

The key lies in visibility and agility—two capabilities enhanced significantly by integrating PlanetTogether APS with ERP platforms like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva.

How APS and ERP Integration Enables Rapid Responsiveness

Let’s break down how the integration between PlanetTogether and leading ERP systems empowers schedulers with the tools they need to respond fast and smart.

Real-Time Visibility Across the Supply Chain

When PlanetTogether APS is integrated with systems like SAP or Microsoft Dynamics, production schedulers gain real-time insight into:

Inventory levels of raw materials, WIP, and finished goods

Supplier lead times and shipment updates

Machine availability and preventive maintenance schedules

Shifting customer order priorities and forecasts

This transparency enables faster, more informed scheduling decisions without requiring separate tools or time-consuming reconciliations.

Scenario Planning and What-If Simulations

One of the standout features of PlanetTogether is its scenario modeling. Suppose a sudden increase in demand for a blood glucose monitoring device occurs. With ERP data synchronized through Oracle or Kinaxis, the scheduler can instantly simulate:

Whether the plant can meet the new demand with current resources

What effect re-prioritizing this product will have on existing production commitments

How to minimize changeover times and labor conflicts

This functionality makes scheduling proactive rather than reactive—a massive leap forward in responsiveness.

Automated Reprioritization and Schedule Re-Optimization

In traditional environments, reprioritizing work orders could take hours or days. But with integrated PlanetTogether APS:

Work orders can be reprioritized in minutes

Production lines are rebalanced to reduce idle time or excess overtime

High-priority SKUs are slotted into the schedule without affecting compliance

Real-time feedback loops between the shop floor and planning team accelerate adjustments

This rapid response ability is especially valuable when serving emergency orders, contract manufacturing, or government health initiatives.

Supporting Regulatory Compliance in Dynamic Schedules

In medical manufacturing, responding quickly is meaningless if you violate regulatory constraints. With PlanetTogether integrated with compliance-aware ERP systems like Aveva or Microsoft, production schedulers can:

Ensure cleanroom utilization complies with FDA or EMA requirements

Maintain full traceability of batch records and audit trails

Avoid scheduling conflicts that could lead to cross-contamination

Manage validation calendars and equipment requalification timelines

This integration ensures that agility does not come at the cost of compliance—a balance that’s vital in the life sciences sector.

Managing Materials and Supplier Volatility

Changes in demand often put pressure on materials and suppliers. Through integration with ERPs like Kinaxis or Oracle, production schedulers using PlanetTogether can:

View real-time supplier availability and adjust production accordingly

Avoid starting jobs with incomplete material kits

Synchronize just-in-time deliveries with schedule changes

Plan around supplier bottlenecks without delaying critical production

This reduces the risk of costly downtime and ensures raw material availability aligns with the new demand signals.

Key Benefits for Production Schedulers in Medical Manufacturing

Accelerated Rescheduling – Minutes instead of days to adapt to demand changes

Reduced Manual Workload – Automation replaces complex spreadsheet juggling

Minimized Compliance Risk – Integrated validation and traceability checkpoints

Optimal Resource Utilization – Balanced labor, equipment, and material planning

Improved On-Time Delivery – Even for urgent or high-volume orders

Building a Future-Ready Scheduling Process

Medical manufacturers are under constant pressure to do more, faster, and better. As market dynamics become more volatile, integrating PlanetTogether APS with leading ERP systems isn’t a luxury—it’s a strategic imperative.

By enabling intelligent, automated, and rapid responses to demand changes, production schedulers become the heroes of operational resilience. They not only ensure timely product delivery but also safeguard public health, drive profitability, and uphold compliance—regardless of what the next curveball might be.

For Production Schedulers in medical manufacturing, the margin for error is shrinking, and the expectations are rising. Integrating PlanetTogether with SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva is the key to moving from reactive firefighting to proactive, agile decision-making.

In a world where lives may depend on timely deliveries, the ability to adapt schedules in real time isn’t just operational excellence—it’s a mission-critical capability.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.