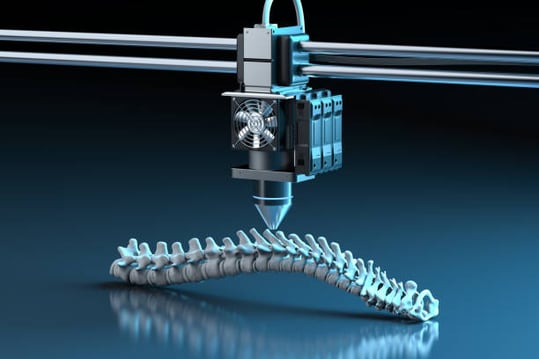

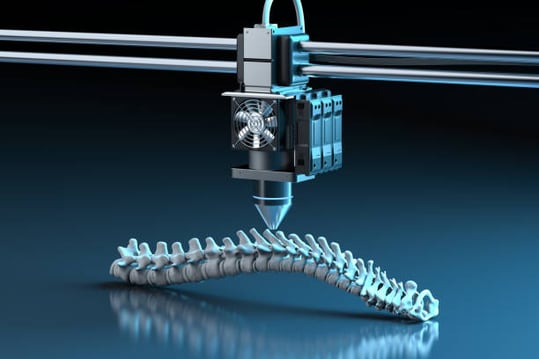

Revolutionizing Medical Manufacturing: The Role of Additive Manufacturing and 3D Printing with APS-ERP Integration

Additive manufacturing, often referred to as 3D printing, has moved beyond the realm of prototyping into full-scale production, particularly in the high-precision world of medical manufacturing. For Manufacturing IT professionals, the convergence of 3D printing technologies with advanced planning and scheduling (APS) systems and enterprise resource planning (ERP) platforms is opening new avenues for flexibility, traceability, and production agility.

In medical manufacturing, where customization, compliance, and rapid innovation are essential, additive manufacturing offers unprecedented opportunities. However, harnessing its full potential requires a digital infrastructure that supports real-time data, seamless workflow integration, and smart scheduling. That’s where the integration of PlanetTogether APS with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva becomes a game-changer.

This blog explores the strategic role of additive manufacturing in medical device production and how APS-ERP integration enables scalable, compliant, and efficient operations.

The Shift Toward Additive Manufacturing in Medical Production

Medical manufacturers are under pressure to innovate rapidly while maintaining regulatory compliance and operational efficiency. Additive manufacturing addresses several of these challenges:

Customization: Personalized implants, prosthetics, and surgical guides tailored to individual patients.

Speed to Market: Rapid prototyping and on-demand production reduce lead times significantly.

Design Freedom: Complex geometries and internal lattice structures improve product performance.

Material Efficiency: Less waste compared to subtractive methods and better use of high-cost materials like titanium and biocompatible polymers.

The widespread adoption of 3D printing technologies is transforming how products are designed, validated, and produced—but only when seamlessly embedded within the broader digital manufacturing ecosystem.

Challenges of Scaling Additive Manufacturing

Despite its advantages, additive manufacturing introduces operational complexities:

Data Overload: High-resolution STL or AMF files generate large data volumes that must be managed.

Traceability Requirements: Regulatory compliance demands full traceability of every part and process.

Production Scheduling: Balancing traditional and additive workflows adds scheduling complexity.

Resource Allocation: Machines, materials, and labor must be coordinated in real time.

Manufacturing IT leaders need to ensure these challenges are addressed through smart systems integration—combining APS for planning optimization with ERP systems for resource visibility and compliance tracking.

How PlanetTogether APS and ERP Integration Enable Additive Manufacturing Success

To realize the full benefits of additive manufacturing, manufacturers must ensure coordination across multiple functions: design, engineering, production, quality, and supply chain. This coordination is achieved through integration between PlanetTogether APS and ERP platforms such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva.

Here’s how:

Unified Scheduling Across Production Types

PlanetTogether APS allows for real-time production scheduling that includes both traditional and additive manufacturing lines. It automatically calculates:

Material requirements for different fabrication types

Optimal print job sequencing

Machine availability and preventive maintenance windows

With ERP integration, real-time data such as sales orders, BOMs, and inventory levels are factored into the scheduling logic, ensuring that additive production fits smoothly into the overall workflow.

Traceability and Compliance Automation

Compliance is critical in medical manufacturing. The combination of APS and ERP ensures every 3D-printed part has a complete digital thread—from design files to production conditions and operator credentials.

PlanetTogether’s scheduling logic can enforce process validation steps, while ERP systems track lot numbers, material batches, and inspection results. This integration supports audits and ensures compliance with FDA, ISO 13485, and EU MDR standards.

Enhanced Capacity Planning

Additive manufacturing machines have unique constraints: build times vary based on part complexity, post-processing is essential, and maintenance must be meticulously scheduled. PlanetTogether APS provides scenario planning and what-if analysis that helps Manufacturing IT teams model the impact of introducing or reassigning 3D printing capacity.

When integrated with ERP systems, planners gain insight into resource consumption and ROI calculations, helping them decide between internal production vs. outsourcing or traditional vs. additive methods.

Demand-Driven Production

Medical manufacturers often deal with volatile and low-volume demand, especially for personalized implants or surgical instruments. With ERP data feeding real-time demand into PlanetTogether APS, additive jobs can be scheduled on-demand, reducing overproduction and inventory holding costs.

This is particularly useful when additive manufacturing is used to produce bridge tooling or custom prototypes prior to full-scale manufacturing.

Strategic Considerations for Manufacturing IT Leaders

To fully enable additive manufacturing in a medical manufacturing environment, Manufacturing IT professionals should:

Prioritize Scalable Integration:

Ensure that the integration between APS and ERP is scalable and can handle multiple production technologies and locations.

Invest in Cybersecurity:

Additive manufacturing involves sensitive design data. Protecting digital assets throughout the ERP-APS pipeline is essential.

Enable Real-Time Feedback Loops:

Machine data, operator input, and quality inspection outcomes should be captured and analyzed in near real-time to continuously optimize the process.

Foster Cross-Functional Collaboration:

Work closely with R&D, quality assurance, and production teams to define workflows that benefit from the flexibility of additive methods.

Plan for Workforce Evolution:

Upskilling staff to manage hybrid production environments—traditional and additive—is critical for success.

Additive manufacturing is no longer just a novelty in medical manufacturing—it’s essential for innovation, responsiveness, and patient-specific care. However, its full potential can only be realized when supported by a robust digital infrastructure that integrates advanced planning with enterprise operations.

For Manufacturing IT leaders, the integration of PlanetTogether APS with ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva is the bridge that transforms 3D printing from a siloed technology into a fully integrated production capability. With the right tools in place, medical manufacturers can produce smarter, faster, and more flexibly—while ensuring compliance and maintaining cost control.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.