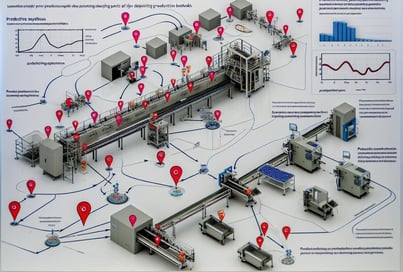

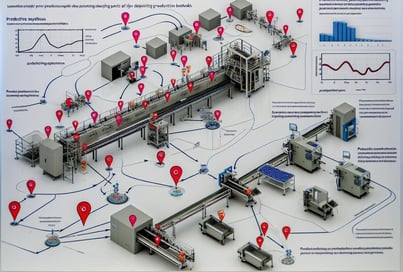

Predictive Analytics for Production Bottleneck Identification

Every minute counts, and any bottleneck in the production process can have a significant impact on the bottom line. For plant managers, identifying and resolving these bottlenecks quickly and effectively is a top priority. Traditional methods of bottleneck identification often fall short, relying on historical data and manual analysis that can be time-consuming and prone to human error.

Enter AI-based predictive analytics—a game-changer in the quest for operational excellence. By harnessing the power of artificial intelligence and machine learning, plant managers can now proactively identify and address potential bottlenecks before they occur, optimizing production processes and maximizing throughput.

In this blog, we'll explore how AI-based predictive analytics, integrated with leading ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva, is revolutionizing the packaging manufacturing industry.

The Challenge in Packaging Manufacturing

Packaging manufacturing is a complex operation involving multiple interconnected processes—from raw material procurement to product assembly and distribution. At each stage of the production cycle, there's the potential for bottlenecks to arise, causing delays, inefficiencies, and increased costs.

Traditional methods of bottleneck identification often rely on manual observation, historical data analysis, and ad-hoc problem-solving. While these methods may provide insights into past performance issues, they fall short when it comes to predicting and preventing future bottlenecks in real-time. As a result, plant managers are left firefighting, reacting to problems as they arise rather than proactively addressing underlying issues.

The Promise of AI-based Predictive Analytics

AI-based predictive analytics offers a proactive approach to bottleneck identification by leveraging advanced algorithms to analyze real-time data from across the production ecosystem. By continuously monitoring key performance indicators (KPIs), such as machine downtime, material availability, and production rates, AI systems can detect patterns, trends, and anomalies indicative of potential bottlenecks.

Moreover, these systems can learn from historical data and adapt their models over time, increasing accuracy and reliability. By providing early warnings and actionable insights, AI-based predictive analytics empowers plant managers to take preemptive measures to mitigate bottlenecks, optimize resource allocation, and ensure smooth operations.

Integration with ERP, SCM, and MES Systems

The true power of AI-based predictive analytics lies in its integration with enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES). These systems serve as the backbone of the packaging manufacturing operation, capturing and managing data from various sources, including production equipment, inventory systems, and customer orders.

By integrating AI-based predictive analytics with leading ERP, SCM, and MES platforms such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, plant managers can achieve seamless data connectivity and interoperability. This enables real-time data exchange and synchronization, ensuring that the AI system has access to the latest information from across the production ecosystem.

PlanetTogether Integration

One notable example of AI-based predictive analytics integration is with PlanetTogether, a leading production planning and scheduling software. By integrating PlanetTogether with ERP, SCM, and MES systems, plant managers can leverage its advanced analytics capabilities to optimize production schedules, identify potential bottlenecks, and improve overall efficiency.

Through real-time data integration and synchronization, PlanetTogether can provide plant managers with actionable insights into production capacity, material availability, and resource utilization. By analyzing historical data and predicting future demand, the system can recommend optimal production schedules that minimize bottlenecks and maximize throughput.

Moreover, PlanetTogether's integration with AI-based predictive analytics enables continuous learning and optimization. By monitoring production performance and adjusting schedules in real-time, the system can adapt to changing conditions and ensure optimal efficiency across the entire manufacturing process.

Implementation Best Practices

Successfully implementing AI-based predictive analytics for production bottleneck identification requires careful planning and execution. Here are some best practices to consider:

Define Clear Objectives: Clearly define the goals and objectives of the AI implementation, including the KPIs that will be monitored and optimized.

Data Quality and Integration: Ensure that data from ERP, SCM, and MES systems is accurate, consistent, and up-to-date. Implement robust data integration processes to synchronize data across systems.

Collaborative Approach: Foster collaboration between plant managers, data scientists, and IT professionals to ensure alignment and accountability throughout the implementation process.

Continuous Improvement: Treat AI-based predictive analytics as an ongoing initiative, continuously monitoring performance and refining models based on feedback and insights.

Change Management: Invest in change management initiatives to ensure buy-in and adoption across the organization. Provide training and support to employees to help them leverage the new capabilities effectively.

AI-based predictive analytics represents a transformative opportunity for plant managers in the packaging manufacturing industry. By leveraging advanced algorithms and real-time data integration, plant managers can proactively identify and address production bottlenecks, optimizing efficiency and driving operational excellence.

AI-based predictive analytics integration with PlanetTogether enables continuous learning and optimization. The integration of PlanetTogether with ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva further enhances the capabilities of AI-based predictive analytics, providing plant managers with actionable insights and real-time visibility into their production operations. With the right strategy and implementation approach, plant managers can unlock the full potential of AI to achieve their production goals and stay ahead in today's competitive market landscape.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.