AI-Driven Optimization of Order Quantities

Purchasing Managers are tasked with the intricate balance of ensuring optimal inventory levels while minimizing costs in industrial manufacturing. Traditional methods of order quantity determination often fall short in adapting to the complexities of modern supply chains.

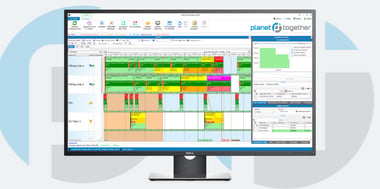

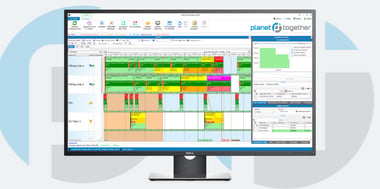

However, with the advent of Artificial Intelligence (AI) and its integration with Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) such as PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, and Aveva, a new era of optimization has emerged.

In this blog, we look into the transformative power of AI-driven optimization of order quantities, exploring its benefits and the integration possibilities with leading systems.

Challenges in Optimizing Order Quantities

Purchasing Managers face a myriad of challenges in optimizing order quantities. Fluctuating demand, lead times, supplier constraints, and carrying costs are just a few factors that complicate the decision-making process. Traditional methods often rely on static models or simplistic calculations that fail to capture the intricacies of these variables. This can lead to suboptimal inventory levels, resulting in increased carrying costs, stockouts, or excess inventory.

The Role of AI in Optimization

AI brings a paradigm shift in how order quantities are determined. By leveraging advanced algorithms and machine learning techniques, AI can analyze vast amounts of data to identify patterns, forecast demand more accurately, and optimize order quantities in real-time. This adaptive approach enables Purchasing Managers to respond swiftly to changes in demand or supply conditions, thereby minimizing costs and maximizing efficiency.

Integration with ERP, SCM, and MES Systems

The integration of AI-driven optimization tools with leading ERP, SCM, and MES systems amplifies its impact. Systems like PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, and Aveva provide a robust infrastructure for data management and process automation. By seamlessly integrating AI capabilities, these platforms empower Purchasing Managers with actionable insights and decision support tools.

Benefits of Integration:

Real-time Visibility: Integration enables real-time data synchronization between different systems, providing Purchasing Managers with a holistic view of inventory levels, demand forecasts, and supplier performance.

Enhanced Forecasting: AI algorithms can analyze historical data, market trends, and external factors to generate more accurate demand forecasts. Integration with ERP and SCM systems ensures that these forecasts are incorporated into procurement planning processes seamlessly.

Dynamic Optimization: With real-time data feeds from MES systems, AI-driven optimization tools can adapt order quantities dynamically based on production schedules, inventory levels, and resource availability.

Cost Efficiency: By optimizing order quantities based on actual demand patterns and supply constraints, integration with ERP and SCM systems helps reduce excess inventory, stockouts, and carrying costs.

Streamlined Procurement: Automated workflows and intelligent alerts streamline the procurement process, enabling Purchasing Managers to focus on strategic decision-making rather than administrative tasks.

Best Practices for Implementation

Data Quality: Ensure data accuracy and consistency across ERP, SCM, and MES systems to maximize the effectiveness of AI-driven optimization algorithms.

Collaborative Approach: Involve stakeholders from different departments, including production, procurement, and finance, in the implementation process to align objectives and foster collaboration.

Continuous Improvement: Monitor key performance indicators (KPIs) regularly and leverage feedback loops to refine optimization algorithms and procurement processes over time.

Change Management: Provide training and support to users to ensure smooth adoption of new tools and processes. Communicate the benefits of integration and AI-driven optimization to build buy-in across the organization.

In an era of unprecedented complexity and volatility, AI-driven optimization of order quantities offers a path to sustainable cost efficiency in industrial manufacturing. By integrating with leading ERP, SCM, and MES systems such as PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, and Aveva, Purchasing Managers can unlock new levels of agility and resilience in their procurement processes.

Embracing this transformative technology is not merely an option but a necessity for those seeking to thrive in the competitive landscape of modern manufacturing. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.