If you're like most manufacturing floor managers, you've most likely used spreadsheets to plan operations. Though this method of production planning services small facilities just fine, many companies quickly outgrow spreadsheet planning. The decision to move past this scheduling strategy may not be obvious at first. This software features low cost, ease of use, universal compatibility, and basic functionality.

Why give up a tried-and-true method that everyone knows how to use?

To understand that, we'd have to go to trace the use of spreadsheets in the manufacturing industry.

Released in 1985, Excel offered a graphical user interface and pull-down menus along with universal compatibility, a first for the industry. Within three years, Excel became the most widely-used spreadsheet software. It makes sense why a high percentage of manufacturing facilities use it for their planning process.

However, Excel poses serious limitations when compared to more robust and full-featured software programs designed specifically for creating and maintaining a production schedule. Below, we’ve outlined some of the common issues that medium to large manufacturing facilities experience with this program.

Why Excel is Not the Solution for Creating Optimized Schedules:

1. Reality of Error Rates

The chance of errors increases with manual entry into these spreadsheets. In fact, a study from the University of Hawaii found that errors in spreadsheets “almost always occur in a few percent of all cells.”

Though a small percentage doesn’t initially sound threatening, once a spreadsheet reaches thousands of info-bearing cells, we’re talking about dozens of errors.

Because of the delicate process involved in your production schedule, a few dozen errors could seriously cost your facility. For example, a miscalculation of a key part in production creates a domino effect resulting in a final assembly delay.

Additionally, you may accidentally delete important information that could change materials statuses or create resource conflicts without even knowing.

2. Difficulty in Analysis

Spreadsheet software lacks the capacity to analyze high volumes of data that often characterize medium to large facilities. Also, spreadsheets don’t accommodate rapidly changing production schedules and multiple project configurations very well. This inability to adjust to change spells disaster for any deadline-driven facility.

3. Leads to Lost Sales

Excel spreadsheets do not allow you to predict future sales based on a realistic schedule. This means that your company is forced to maintain a higher inventory which can increase costs or you may be failing at meeting delivery times.

Using an Advanced Planning and Scheduling software allows you to maintain your inventory based on a realistic schedule and meet your delivery dates. This will increase your customer satisfaction and increase your profits.

4. Lack of Structure

Inherently single-user, spreadsheets enable one user to control the master copy. However, when multiple users need equal access, the odds of data misinterpretation and entry error increase. Also, spreadsheet software cannot track data in real time making on-site analysis quite difficult.

5. Inevitable Uncertainties

Spreadsheets are tools of calculation, not analytics. If your facility requires ranges, forecasts, re-planning, or modeling, you’ll quickly discover the limitations of using spreadsheet software. The result: utilizing human judgment based on limited evidence. Software with analytic skills offers far better precision in identifying trends and interpreting data.

6. More Labor, Less Income

Finally, having to use Excel as your main planning and scheduling tool requires more individuals that are solely focused on it. As a result, you are wasting time and resources on a tool that should be working on its own to create the most optimized production schedule in a fraction of the time.

While Excel is a fair solution when your ERP doesn't allow for scheduling, it can also cause data and time loss. Additionally, foresight is impossible with Excel which will cause you to put more energy, time, and money to rush orders.

With an Advanced Planning and Scheduling system, you will find more time to focus on creating the most efficient production schedule without losing money.

When Production Gets Too Complex for Spreadsheets

As manufacturers scale, they begin facing a complexity threshold that spreadsheets simply weren’t designed to handle. What starts as a simple calendar of operations quickly becomes a juggling act involving:

-

Dozens of SKUs with varying routings and constraints

-

Labor scheduling across overlapping shifts

-

Machine maintenance windows and breakdowns

-

Urgent customer orders that reshape priorities

-

Inventory dependencies and supplier delays

At this scale, planners spend most of their day reacting instead of planning. Spreadsheets don’t offer visibility across departments or provide alerts when the plan breaks. They can’t prioritize high-value orders or optimize resource utilization. And they don't help you model tradeoffs between lead time, cost, and throughput.

In short, spreadsheets stop being tools and start being traps.

Enter Advanced Planning and Scheduling (APS) Software

Modern manufacturers are embracing Advanced Planning and Scheduling Software to meet the rising demands for customization, speed, and efficiency.

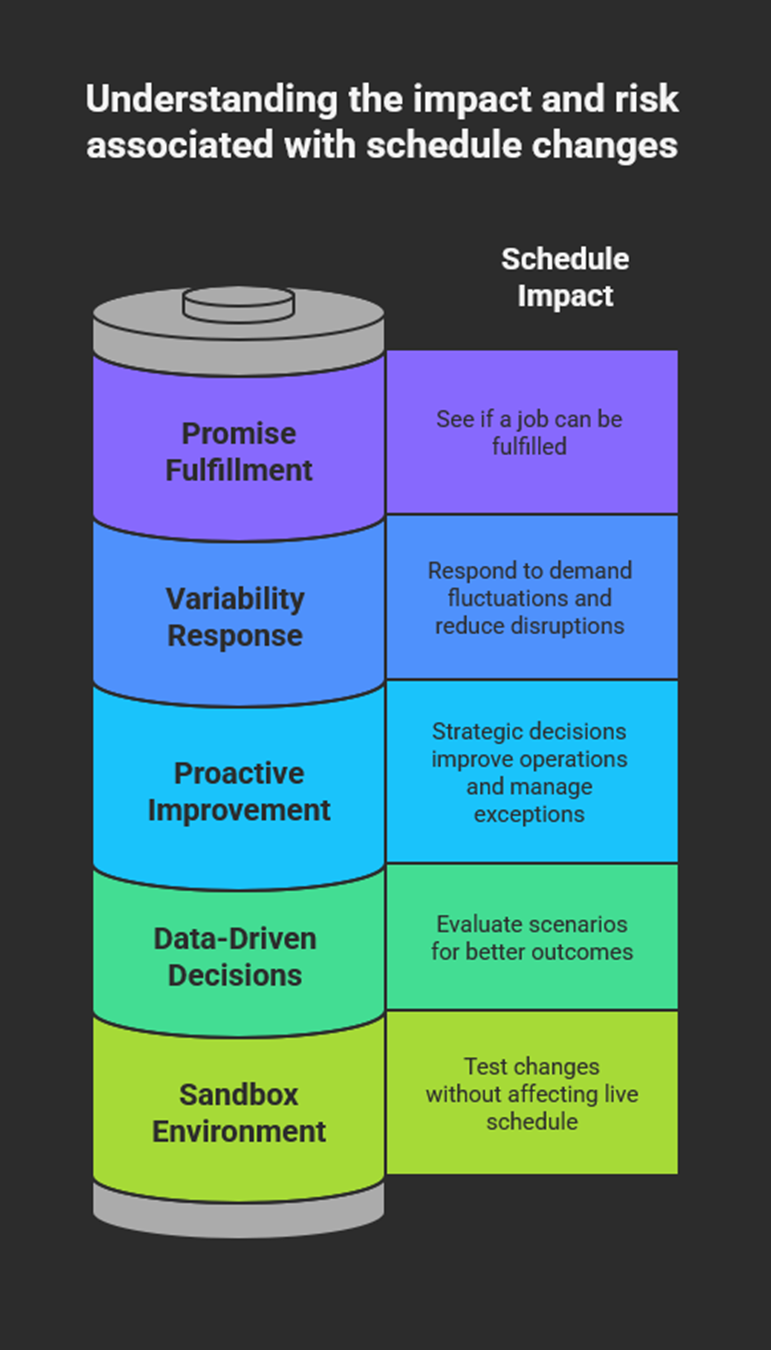

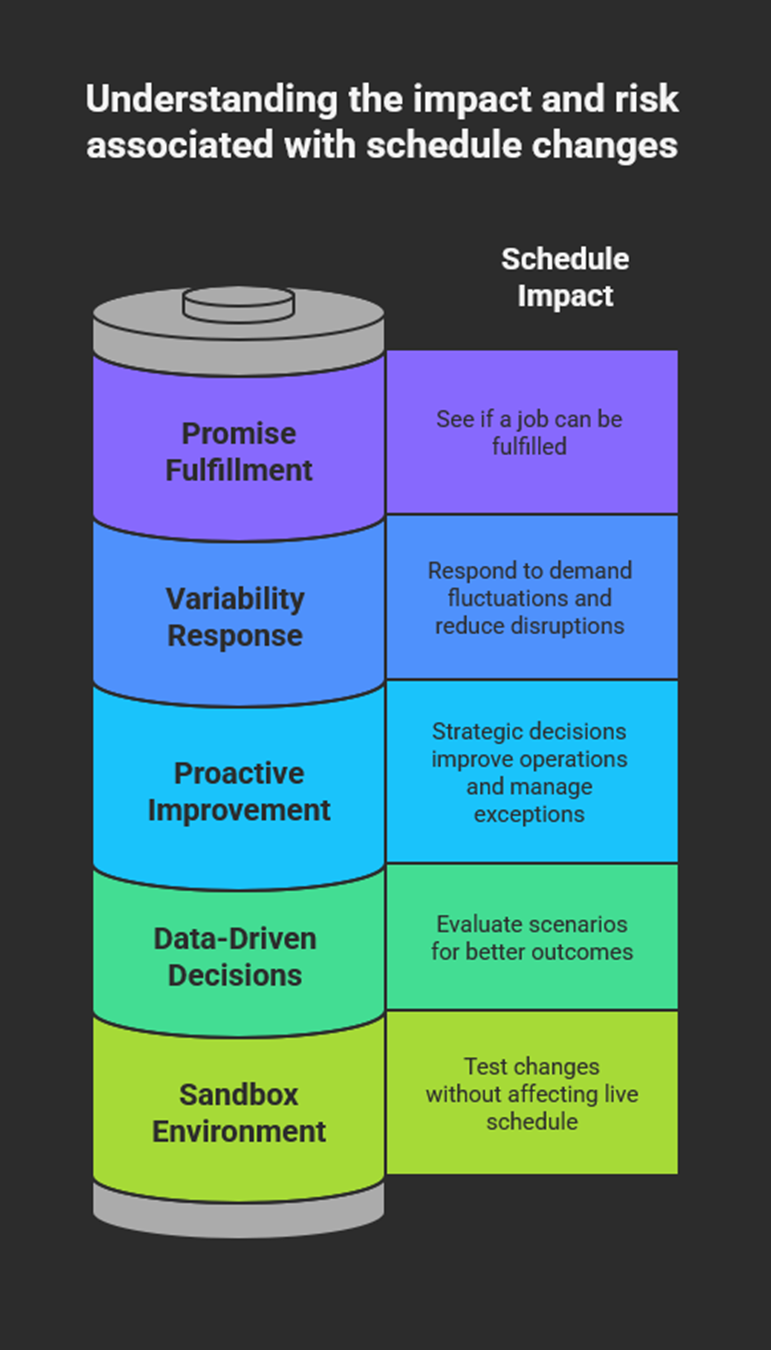

APS systems go beyond spreadsheets and traditional ERP scheduling tools by providing:

-

Optimization engines that generate efficient schedules in seconds

-

Real-time data integration from MES and ERP systems

-

Advanced forecasting and scenario planning

-

Constraint-based scheduling to account for material, labor, and machine limits

With APS, you’re not just making a schedule—you’re making the best schedule possible for your current conditions and strategic goals.

PlanetTogether APS delivers a comprehensive solution tailored for manufacturing operations of all sizes. It helps planners:

-

Create optimized schedules that balance efficiency with delivery performance

-

Maximize throughput on bottleneck resources

-

Reduce inventory levels by aligning supply with real demand

-

Enable collaboration across departments and facilities

-

Simulate what-if scenarios for smarter decision-making

Our system integrates with popular ERPs like SAP, Microsoft Dynamics, and Oracle, eliminating silos and enhancing scheduling capabilities where ERPs fall short.

Spreadsheets were great for 1985. But your plant runs in real time, not cell-by-cell.

With an APS like PlanetTogether, you gain the tools to schedule faster, plan smarter, and deliver better. It’s not just about ditching Excel—it’s about advancing your operations.

Ready to make the leap? Request a Demo or try our Sequence Optimizer today.

.gif?width=900&height=900&name=Copia%20de%20Instagram%20Post%20(1).gif)

APS Resources

.gif?width=900&height=900&name=Copia%20de%20Instagram%20Post%20(1).gif)