Achieving Full Compliance in Medical Device Production: How APS Integration Enhances Regulatory Confidence

In medical device manufacturing, compliance is not optional—it is the foundation of operational legitimacy, patient safety, and global market access. Regulatory bodies such as the FDA, EMA, and ISO demand strict adherence to protocols, documentation standards, and traceability frameworks. For Operations Directors managing the delicate balance of regulatory compliance, production efficiency, and cost control, the pressure is unrelenting.

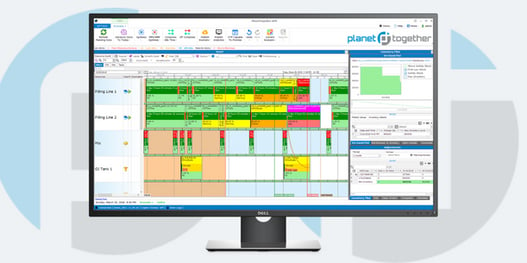

In this environment, adopting an integrated Advanced Planning and Scheduling (APS) system such as PlanetTogether, in conjunction with enterprise platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, is not just a value add—it’s a strategic imperative. Together, these solutions provide the data transparency, process synchronization, and compliance management that modern medical manufacturing demands.

This blog explores how Operations Directors can leverage APS-ERP integration to meet and exceed regulatory compliance goals while streamlining production and safeguarding product quality.

The Compliance Challenge in Medical Device Manufacturing

Medical device production is governed by complex regulations that require:

Complete traceability of raw materials, processes, and components.

Robust documentation of quality assurance (QA) activities.

Real-time deviation management and corrective/preventive action (CAPA) systems.

Validation of production equipment and software used in the manufacturing process.

Change control procedures aligned with Good Manufacturing Practices (GMP).

Failure to comply can result in product recalls, fines, suspended licenses, or worse—harm to patients. But compliance requirements also generate a data burden and introduce operational rigidity if not handled with modern digital tools.

Why APS Matters for Compliance

Advanced Planning and Scheduling (APS) systems like PlanetTogether can deliver compliance benefits far beyond traditional production planning methods. Here’s how:

Enabling Real-Time Traceability

PlanetTogether’s APS system, when integrated with ERP systems such as SAP or Oracle, allows for real-time visibility into material genealogy and production workflows. Every component can be traced through its lifecycle—from supplier delivery, through each manufacturing process, to final shipment. This end-to-end traceability is vital for complying with FDA 21 CFR Part 11 and ISO 13485 standards.

Improving Audit Readiness

With PlanetTogether integrated into platforms like Microsoft Dynamics or Kinaxis, audit documentation is no longer a fire drill. APS systems capture time-stamped records of activities, quality checks, and production events. This automatic recordkeeping ensures you are always audit-ready with minimal disruption to operations.

Streamlining Change Control

Changes in design, process, or supplier can trigger compliance events that must be documented and managed carefully. PlanetTogether enables synchronized change control by aligning planning data with ERP-managed specifications and quality processes. This ensures that production changes do not violate regulatory protocols or delay compliance approvals.

Enhancing Validation Processes

Validation is not just for machines—your scheduling systems must also be validated. APS platforms integrated with validated ERP systems like those offered by SAP or Aveva allow you to lock down processes, user access, and data inputs in accordance with regulatory expectations. This builds trust with inspectors and customers alike.

Key Features of APS-ERP Integration for Compliance

Seamless integration between PlanetTogether and platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva empowers medical manufacturers with a robust infrastructure for compliance management. Below are some standout capabilities:

• Batch-Level Scheduling with Genealogy Mapping

Track and plan every lot or batch at the most granular level. PlanetTogether’s APS engine enables batch-centric planning, which is then linked to ERP master data for precise genealogy tracking—ideal for device history records (DHR) compliance.

• Automated Quality Gate Enforcement

Integration with ERP quality modules allows PlanetTogether to automatically schedule and respect quality hold points, QA release stages, and inspection deadlines. This ensures nothing is manufactured or shipped without proper checks.

• Electronic Signatures and Audit Trails

Comply with electronic signature requirements through ERP systems that support 21 CFR Part 11. PlanetTogether can trigger and record scheduling decisions and approvals in compliance with electronic recordkeeping standards.

• Harmonized Data and Reporting

Reporting across planning, scheduling, and execution becomes unified. Whether regulators require batch records, deviation logs, or KPI summaries, the integrated APS-ERP environment provides quick and accurate retrieval of validated data.

In medical manufacturing, compliance isn't simply about checking boxes—it's about protecting lives and preserving reputational integrity. For Operations Directors, the right technology stack is crucial. Integrated solutions that combine the precision of PlanetTogether APS with the robust infrastructure of SAP, Oracle, Microsoft, Kinaxis, or Aveva offer an unbeatable combination.

These tools empower you to streamline production planning, enhance traceability, automate validation, and maintain constant audit readiness—all without sacrificing efficiency or profitability.

The message is clear: achieving full compliance doesn’t have to mean compromising productivity. With the right APS-ERP integration, compliance becomes an enabler of operational excellence—not a bottleneck.

Are you ready to elevate compliance in your medical manufacturing operations? Explore how PlanetTogether integrates seamlessly with your ERP environment to help you achieve full regulatory confidence. Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Medical Manufacturing, Streamlining Change Control, Enabling Real-Time Traceability, Improving Audit Readiness, Enhancing Validation Processes

LEAVE A COMMENT