Smart Manufacturing Control Systems for Adaptive Process Control

The ability to adapt and optimize manufacturing processes in real-time is essential for success. For packaging manufacturers, where efficiency, quality, and agility are critical, implementing smart manufacturing control systems is not just an option but a necessity. These systems leverage advanced technologies to enable adaptive process control, ensuring seamless operations and enhanced productivity.

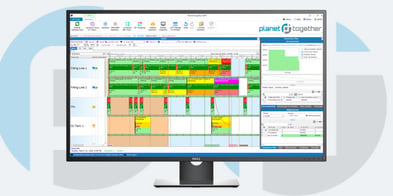

One of the key components in this journey towards smart manufacturing is the integration between production planning software like PlanetTogether and Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) such as SAP, Oracle, Microsoft, Kinaxis, Aveva, and others. This integration streamlines data flow, enhances visibility, and empowers decision-makers with actionable insights across the manufacturing ecosystem.

In this blog, we look into the significance of smart manufacturing control systems, explore the integration between PlanetTogether and leading ERP, SCM, and MES platforms, and highlight the benefits they offer to packaging manufacturing facilities.

Smart Manufacturing Control Systems

Smart manufacturing control systems represent a paradigm shift in how industrial processes are monitored, analyzed, and optimized. At the core of these systems lie advanced technologies such as Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), and Big Data analytics. By harnessing real-time data from sensors, machines, and production lines, these systems enable predictive and prescriptive insights, driving continuous improvement and efficiency gains.

Key features of smart manufacturing control systems include:

Real-time Monitoring: Continuous monitoring of production processes to detect deviations, anomalies, and inefficiencies promptly.

Predictive Maintenance: Anticipating equipment failures and scheduling maintenance activities proactively to minimize downtime and optimize asset utilization.

Adaptive Control: Dynamically adjusting production parameters based on changing demand, resource availability, and market conditions to optimize throughput and resource utilization.

Data Analytics: Leveraging advanced analytics techniques to extract actionable insights from vast amounts of production data, enabling data-driven decision-making.

Seamless Integration: Integration with other enterprise systems such as ERP, SCM, and MES to ensure data consistency, visibility, and alignment across the organization.

Integration Between PlanetTogether and ERP, SCM, MES Systems

The integration between PlanetTogether, a leading production planning and scheduling software, and prominent ERP, SCM, and MES platforms revolutionizes the way packaging manufacturers manage their operations. Whether it's SAP, Oracle, Microsoft Dynamics, Kinaxis RapidResponse, Aveva MES, or other systems, seamless integration offers several benefits:

Unified Data Environment: Integration eliminates data silos by synchronizing production schedules, inventory levels, resource allocations, and order statuses between PlanetTogether and ERP/SCM/MES systems. This ensures that all stakeholders have access to real-time, accurate information for informed decision-making.

Streamlined Workflows: Automated data exchange between production planning and enterprise systems streamlines workflows and reduces manual data entry errors. For example, when a new order is created in the ERP system, it automatically reflects in PlanetTogether for production planning and scheduling, ensuring alignment between demand and capacity.

Enhanced Visibility: Integration provides end-to-end visibility into the entire manufacturing process, from order inception to delivery. This visibility enables better tracking of production progress, material usage, and resource utilization, facilitating proactive intervention when deviations occur.

Optimal Resource Utilization: By integrating production plans with resource availability and capacity constraints from MES systems, packaging manufacturers can optimize resource utilization and minimize production bottlenecks. This ensures efficient use of labor, equipment, and materials, ultimately driving cost savings and improved efficiency.

Agile Response to Changes: Integration enables rapid response to changes in demand, supply chain disruptions, or production constraints. PlanetTogether can dynamically adjust production schedules based on real-time data from ERP, SCM, and MES systems, ensuring agility and responsiveness to market dynamics.

Benefits of Smart Manufacturing Control Systems Integration

The integration between PlanetTogether and ERP, SCM, MES systems offers a multitude of benefits to packaging manufacturing facilities:

Improved Operational Efficiency: By synchronizing production plans with enterprise systems, manufacturers can optimize resource utilization, minimize downtime, and improve overall operational efficiency.

Enhanced Product Quality: Real-time monitoring and adaptive control enable early detection of quality issues and timely interventions, resulting in improved product quality and reduced waste.

Increased Agility: Integration enables rapid adaptation to changing market conditions, customer demands, and supply chain disruptions, allowing manufacturers to stay competitive in dynamic environments.

Cost Savings: By eliminating inefficiencies, reducing downtime, and optimizing resource usage, integrated smart manufacturing control systems help lower production costs and improve profitability.

Scalability and Growth: The scalability of integrated systems allows manufacturers to expand operations seamlessly, without compromising efficiency or visibility. This scalability supports business growth and expansion into new markets.

In packaging manufacturing, smart manufacturing control systems powered by integration between PlanetTogether and leading ERP, SCM, and MES platforms are indispensable tools for achieving adaptive process control. By harnessing the power of real-time data, advanced analytics, and seamless connectivity, these systems empower manufacturers to optimize operations, enhance quality, and drive sustainable growth in an increasingly competitive landscape.

Embracing smart manufacturing is not just about staying ahead—it's about redefining what's possible in the realm of industrial excellence. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.