One of the most challenging aspects of planning in manufacturing is predicting what the demand for your items will be. In a perfect world, manufacturers would be able to predict exactly how much of each item will be bought by customers, allowing the production plant to produce that exact amount at the right time.

However, the reality of demand planning is more complicated than that. This is especially true as demand is driven by consumers - and is constantly changing. Demand Planning has become an essential part of production planning and scheduling and uses many tools that can help manufacturers predict how much of each item will be required.

What is Demand Planning?

Demand Planning is a process within supply chain management that aims to predict future demand for items so that manufacturers can produce the right amount of items to supply those demands.

In general, demand planning starts by analyzing past demand and sales data. This will allow you to generate a demand forecast based on historical data and help you identify trends in demand for different products.

Once the forecast is generated and implemented, it is important to compare it to actual sales demand and adjust it accordingly. Over time, you will be able to increase the accuracy of your demand forecasts.

Why is Demand Planning Important?

Poorly executed demand plans can be extremely costly to manufacturing organizations. If you overestimate the demand, you risk being stuck with excess inventory that might become obsolete or require to be sold at a discounted price. In the food manufacturing industry, excess inventory is especially risky as food can only be kept for a certain period of time before it spoils.

On the other hand, having too little inventory is just as bad. If you have customers who are putting in orders for items that you cannot deliver in just time, you risk losing revenue and damaging your reputation.

Varying demand can alter your production negatively. This is why demand planning has become a necessity for production facilities around the globe and has enabled manufacturing operations to be prepared for unexpected changes in demand. A good demand plan will allow you to adjust quickly to fluctuations in demand.

Improving Demand Planning

Predicting the future with total exactness is currently impossible. However, there are strategies and tips that can help increase the accuracy of your forecasts. Even if demand planning has been implemented into your manufacturing operation, there is always room for improvement. Therefore, here are four tips that will assist you in improving your demand planning.

1. Understand the Unpredictability

There is a multitude of internal and external factors that can make demand unpredictable. This is why it is important to start by having a thorough understanding of your supply chain and highlight areas that are more unpredictable. This will allow you to focus on those areas to increase the accuracy of your demand forecasts.

One area that can help improve your demand planning is to understand the visibility of your supply chain. This means identifying whether you have enough visibility in the state and location of your raw materials, production operations, inventory levels, shipping, and distribution. Increasing visibility will help you create better forecasts and allow you to align your demand, production, and inventory levels.

Unpredictability is common in demand forecasting due to the presence of demand volatility in manufactured goods. However, you can start by analyzing your demand data to highlight any products that have had a consistent demand. This will help you identify which products you should spend more time on during your forecast generation.

2. Keep it Simple

Many manufacturing operations believe in the misconception that a more complex system will improve demand planning. This will depend mainly on the operation, but finding a simple, advantageous method that is best suited for your operation will be a proper solution for your demand planning.

These methods include the following:

- Examination Method - taking a deeper look at the proficiency of leaders

- Time Series Method - viewing historical data

- Consensus Method - utilization of leaders across various departments or organizations

Ridding yourself of the mindset that complexity is best and utilizing simpler, much more capable methods will improve your approach toward demand planning.

3. Expect the Unexpected

The goal of demand planning is to prepare for the future which is why it is important to consider various scenarios and situations. In 2020, we have observed the external impacts of the coronavirus global pandemic on demand.

Supply chains were not prepared for such surges in demand which left many stores without stock for common items.

This is why it is crucial to have a plan that is ready to be implemented at a moment’s notice to allow your manufacturing operation to handle unfavorable circumstances at any given time.

Flexible and well-developed plans are extremely beneficial to your production facility. To effectively prepare, manufacturing operations should do the following:

- Thoroughly plan for the future for ALL possible circumstances

- Enable an efficient and flexible method that will allow you to quickly optimize production

- Locate other flexible partners or businesses

Preparing for variations in demand and worst-case scenarios will effectively enable your manufacturing operation to quickly implement a solution to demand challenges.

4. Use Technology

One of the most valuable techniques to improve demand planning is to use technology. An Advanced Planning and Scheduling (APS) software can enhance your demand planning through an integrated system of agility and efficiency.

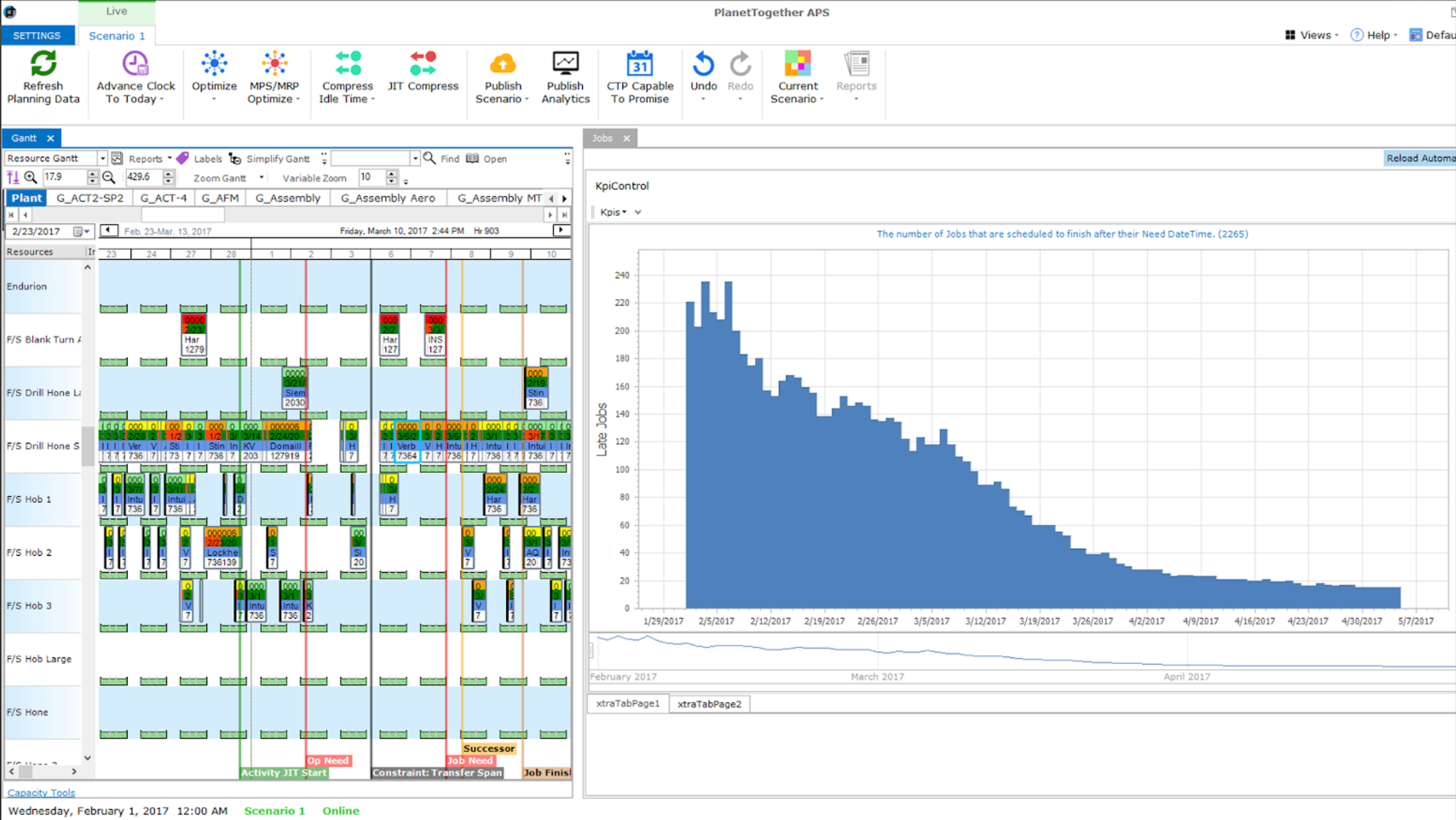

PlanetTogether’s APS has many features that will allow you to make the most of your demand data. This integrated system will save you time and money while generating a demand plan as it allows accurate forecasting and simple schedule adjustments.

PlanetTogether offers reports and analytics using Power BI to allow you to gain a better understanding of your products and demand. This will allow you to gain visibility into you operations.

What-If Scenarios can be used to visualize the effects of varying demand and prepare contingency plans in advance. This will allow you to know which strategy is the best to handle any situation, should it arise in the future.

These capabilities will enhance your production facility and optimize your production so that you can be prepared to face changes in demand and respond quickly. PlanetTogether will help you meet your demand and maintain a competitive advantage in the market.

With PlanetTogether, we are able to make strategic decisions that improve operations. We can proactively prepare for anticipated increases or slowdowns in demand.

DICK MARX, MATERIALS MANAGER, KNAPHEIDE TRUCK EQUIPMENT

Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling Softwares have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free trial or demo!

Related Visualizing Demand Video

APS Resources