Big Data Analytics for Informed Decision-Making

Operations Directors are constantly seeking innovative solutions to enhance efficiency, optimize production processes, and ensure regulatory compliance. With the advent of Industry 4.0 technologies, the utilization of big data analytics has emerged as a game-changer in driving actionable insights and informed decision-making across all facets of production.

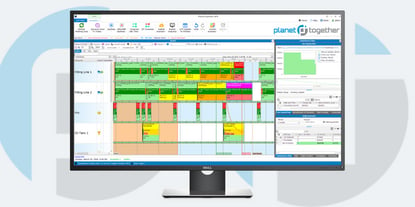

In this blog, we'll explore how Operations Directors in pharmaceutical manufacturing facilities can harness the power of big data analytics to unlock hidden efficiencies and streamline operations. Additionally, we'll look into the integration between PlanetTogether, a leading production planning and scheduling software, and prominent ERP (Enterprise Resource Planning), SCM (Supply Chain Management), and MES (Manufacturing Execution Systems) solutions such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, to facilitate seamless data exchange and optimize decision-making processes.

Big Data Analytics in Pharmaceutical Manufacturing

Pharmaceutical manufacturing involves complex processes, stringent regulatory requirements, and intricate supply chain dynamics. Traditionally, decision-making in this industry relied heavily on historical data, manual analysis, and subjective judgment. However, the volume, velocity, and variety of data generated within modern manufacturing environments have surpassed the capabilities of conventional analytical methods.

Big data analytics offers a transformative approach by harnessing advanced algorithms, machine learning techniques, and real-time data processing to derive actionable insights from vast datasets. By leveraging big data analytics, Operations Directors can:

Enhance Predictive Maintenance: Predictive analytics algorithms can analyze equipment performance data in real-time to predict maintenance requirements accurately. This proactive approach minimizes downtime, reduces maintenance costs, and ensures uninterrupted production.

Optimize Production Planning and Scheduling: Advanced analytics tools enable Operations Directors to optimize production schedules based on demand forecasts, resource availability, and capacity constraints. By balancing workloads and minimizing changeover times, pharmaceutical manufacturers can maximize throughput and meet customer demand effectively.

Improve Quality Control: Big data analytics facilitates the monitoring and analysis of process parameters, environmental conditions, and quality metrics in real-time. This proactive approach enables early detection of deviations, enhances product quality, and ensures compliance with regulatory standards.

Enhance Supply Chain Visibility: By integrating data from suppliers, distributors, and internal systems, Operations Directors can gain comprehensive visibility into the entire supply chain. This transparency enables proactive risk management, timely inventory replenishment, and efficient order fulfillment.

Integrating PlanetTogether with ERP, SCM, and MES Systems

Effective utilization of big data analytics requires seamless integration between production planning and scheduling software like PlanetTogether and other enterprise systems such as ERP, SCM, and MES. Integration enables the bi-directional flow of data, synchronization of processes, and automation of workflows, thereby eliminating silos and driving operational efficiency.

Let's explore how integration with prominent enterprise systems enhances decision-making capabilities:

SAP Integration: SAP is a leading ERP solution widely adopted in the pharmaceutical industry for its robust functionalities in finance, procurement, and supply chain management. By integrating PlanetTogether with SAP, Operations Directors can synchronize production schedules with demand forecasts, optimize resource allocation, and streamline order fulfillment processes.

Oracle Integration: Oracle offers comprehensive SCM solutions designed to optimize supply chain operations, inventory management, and logistics. Integration between PlanetTogether and Oracle enables real-time visibility into inventory levels, demand fluctuations, and production schedules, allowing Operations Directors to make data-driven decisions to mitigate supply chain risks and enhance responsiveness.

Microsoft Dynamics Integration: Microsoft Dynamics provides a suite of ERP and CRM solutions tailored to the needs of pharmaceutical manufacturers. Integration with PlanetTogether enables seamless data exchange between production planning, inventory management, and customer relationship management systems, empowering Operations Directors to align production schedules with customer demands and market trends.

Kinaxis Integration: Kinaxis offers a cloud-based SCM platform that facilitates end-to-end supply chain planning and optimization. By integrating PlanetTogether with Kinaxis, Operations Directors can leverage advanced analytics capabilities to perform scenario analysis, simulate production scenarios, and mitigate supply chain disruptions effectively.

Aveva Integration: Aveva provides MES solutions designed to improve manufacturing efficiency, quality control, and regulatory compliance. Integration with PlanetTogether enables real-time synchronization of production schedules, work orders, and quality data, empowering Operations Directors to monitor and optimize manufacturing processes for maximum efficiency and compliance.

In the era of digital transformation, pharmaceutical manufacturing facilities must embrace the power of big data analytics to drive operational excellence and maintain a competitive edge. By leveraging advanced analytics tools and integrating production planning and scheduling software like PlanetTogether with ERP, SCM, and MES systems, Operations Directors can harness the full potential of data to make informed decisions, optimize production processes, and ensure regulatory compliance.

As the pharmaceutical industry continues to evolve, Operations Directors who embrace data-driven decision-making will emerge as leaders in driving efficiency, innovation, and sustainability across their organizations. With the right technology infrastructure and strategic vision, pharmaceutical manufacturers can navigate the complexities of modern production environments with confidence and agility, positioning themselves for long-term success in a rapidly changing market landscape.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.