Meeting Customer Demands with Agility: Advanced Scheduling for Industrial Manufacturers

In today’s volatile and customer-centric manufacturing environment, speed, flexibility, and accuracy in fulfilling customer orders are non-negotiable. Industrial manufacturers face growing pressure to deliver customized, high-quality products at shorter lead times—all while navigating fluctuating raw material availability, machine downtime, workforce constraints, and supply chain disruptions.

For Production Schedulers, this reality presents a high-stakes balancing act: how do you ensure on-time delivery, minimize bottlenecks, and react quickly to shifting customer demands?

The answer lies in digital agility—specifically, Advanced Planning and Scheduling (APS) systems like PlanetTogether, integrated seamlessly with ERP platforms such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva. This integration empowers schedulers to align customer expectations with shop floor reality, turning production chaos into a competitive advantage.

The Evolving Nature of Customer Demands in Industrial Manufacturing

Customer expectations have shifted dramatically. It’s no longer just about meeting a forecasted demand—today’s customers expect:

Shorter lead times

Greater order flexibility and customization

Transparent communication and delivery tracking

Consistent quality and performance

These demands require real-time responsiveness from production teams. Unfortunately, many industrial manufacturers still rely on spreadsheets or legacy MRP systems that struggle to keep pace with modern demand complexity. Static schedules become outdated in minutes, and the lack of visibility into capacity and resource conflicts leads to delays, costly overtime, and missed SLAs.

Why Production Scheduling Must Go Beyond ERP Alone

ERPs are critical for managing business transactions, but they fall short in handling the dynamic, constraint-based scheduling that shop floors require. Production schedulers need a solution that can model:

Machine capacities and setups

Workforce availability and shifts

Inventory constraints

Prioritization rules based on customer SLAs

Rush orders and real-time disruptions

That’s where PlanetTogether APS comes in. It bridges the gap between high-level planning and real-time execution by enabling constraint-based finite capacity scheduling. But the real magic happens when PlanetTogether is integrated with your ERP system—be it SAP, Oracle, Microsoft, Kinaxis, or Aveva.

How Integration with ERP Unlocks Responsive Scheduling

When PlanetTogether is connected to your ERP, the result is a real-time feedback loop between customer demand, resource capacity, and production execution. Here's what this looks like in practice:

Real-Time Demand Visibility

Through ERP integration, customer orders, forecasts, and priority updates automatically sync into PlanetTogether. Schedulers always work with up-to-date demand signals, allowing them to prioritize urgent jobs and reduce time-to-delivery.

Capacity-Conscious Planning

Unlike MRP modules that assume infinite capacity, PlanetTogether uses real-world constraints—machines, labor, tooling—to create feasible, optimized schedules. When changes occur (e.g., a line goes down), the scheduler receives an alert and can adjust in minutes.

Scenario Modeling for ‘What-If’ Analysis

Need to evaluate the impact of a large rush order or maintenance shutdown? PlanetTogether enables scenario modeling so you can forecast outcomes without disrupting live schedules—vital for making customer-centric decisions under pressure.

Improved On-Time Delivery

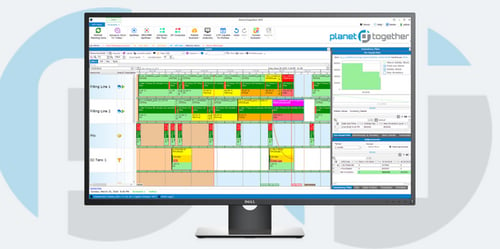

With automated alerts, visual Gantt charts, and rule-based prioritization, PlanetTogether helps production teams stay ahead of due dates, meeting demanding SLAs with higher confidence and consistency.

Lean and Agile Execution

ERP-APS integration helps eliminate overproduction, excess inventory, and idle time. Schedulers can see where waste is accumulating and reassign jobs to maintain flow without firefighting.

Benefits for Production Schedulers: What You Gain

Schedulers in industrial manufacturing aren’t just calendar managers—they’re the conductors of operational efficiency. With an integrated APS like PlanetTogether, you gain:

Control

Instead of reacting to chaos, you proactively manage demand shifts, equipment breakdowns, and labor shortages.

Speed

Create, revise, and publish new schedules in minutes—not hours or days—without sacrificing accuracy.

Transparency

Track every order’s path from request to delivery, and communicate lead times confidently to customer service and sales.

Optimization

Balance competing priorities—rush jobs vs. cost-efficiency, machine utilization vs. maintenance windows.

Collaboration

Coordinate easily with procurement, maintenance, and operations through a centralized, visual platform that everyone can trust.

Industry Impact: Meeting Demand without Adding Cost

In the high-stakes world of industrial manufacturing, meeting customer demand isn’t just about making products—it’s about building reliability, trust, and competitive differentiation.

With the right APS solution, you can:

Increase on-time delivery rates without expanding capacity

Reduce downtime through smarter resource allocation

Improve customer satisfaction through agile responsiveness

Scale production planning without hiring more schedulers

The key lies in integration—aligning your ERP's transactional backbone with the real-time, intelligent decision-making capabilities of PlanetTogether.

For industrial Production Scheduler, the role is no longer confined to the back office—it’s strategic, cross-functional, and customer-facing. Meeting customer demand is about more than just avoiding stockouts or shipping on time. It's about building agile, intelligent scheduling environments that adapt in real-time and align with business goals.

By embracing APS-ERP integration with PlanetTogether, schedulers can elevate their role and drive lasting value across the entire production ecosystem.

The question isn’t whether you can meet demand—it's how fast and how smartly you can do it.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Industrial Manufacturing, PlanetTogether Software, Improved on-time delivery, Integrating PlanetTogether, Real-Time Demand Visibility, Scenario Modeling for ‘What-If’ Analysis, Capacity-Conscious Planning, Lean and Agile Execution

LEAVE A COMMENT