In the mobility sector, where precision and speed are everything, there’s little room for planning errors. One leading global manufacturer knew this too well. Despite their reach and reputation, their internal planning system couldn’t keep up. Built on an outdated infinite-capacity model, the system created plans that looked fine on paper—but fell apart in execution.

Manual corrections were common. Critical data from upstream systems was often ignored. And worst of all, production teams couldn’t trust the schedule to reflect real constraints, leading to delays, routing errors, and missed opportunities.

The Challenge: Complexity Without Control

-

Manual interventions were the norm, leading to lost time and frequent errors.

-

Disjointed systems meant that critical planning data didn’t flow between MES, ERP, and production.

-

Routing inefficiencies created bottlenecks, and too often the right job didn’t land with the right person.

-

Planning relied heavily on tribal knowledge, making the process vulnerable and inefficient.

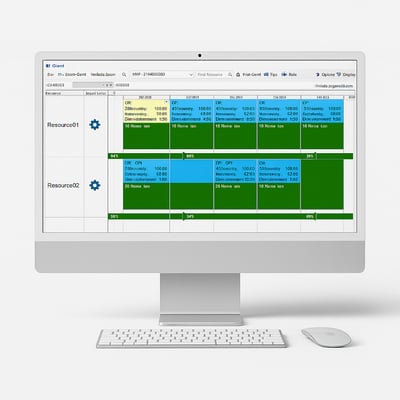

The Solution: Real-Time Integration, Smarter Execution

To solve these problems, the company introduced a modern planning platform that integrated directly with their MES and partner systems. The transition included:

-

Tailored planning rules to match operational reality

-

Real-time syncing of production orders from MES to scheduling

-

Clear interfaces that enabled every planner to make confident, data-backed decisions

-

Finite capacity logic that aligned actual availability with production goals

Results That Spoke for Themselves

-

Reduced planning workforce needs thanks to automated plan generation

-

Increased scheduling accuracy, with fewer interventions

-

Better communication across workshops and faster realization of plans

-

Less dependency on individual planners—schedules were now driven by systems, not memory

From the Planning Floor

“We’ve replaced plans that depended on memory and manual work with ones based on data and analysis. It’s not just easier—it’s smarter.”

The Takeaway

This isn’t just a story about software—it’s about what happens when planning teams are empowered with tools that match the complexity of their operations. When production, systems, and people work together in harmony, businesses move faster, smarter, and with greater confidence.

📅 Ready to upgrade your planning? Schedule a demo now.

👉 Discover how they did it—read the full case study.